24 Hour Service

24 Hour Service- 800.825.3222

- Now Hiring

- Request A Quote

Blog

Top 5 Rotary Air Compressors to Buy in 2025: Reviews and Buying Guide

As industries continue to evolve, the demand for efficient and reliable compressed air solutions remains paramount. Among various options, the rotary air compressor stands out due to its sophisticated mechanism and ability to deliver consistent air pressure, making it suitable for a range of applications from manufacturing to construction. According to a market research report by Grand View Research, the global air compressor market size was valued at approximately USD 30 billion in 2021 and is projected to grow at a compound annual growth rate (CAGR) of over 5% through 2028. This growth is indicative of the increasing adoption of rotary air compressors, which are known for their energy efficiency and lower operational costs compared to their reciprocating counterparts.

Moreover, a study published by Allied Market Research highlights that rotary air compressors account for a significant market share, driven by advancements in technology and the expanding industrial sector. The versatility and durability of rotary air compressors make them a preferred choice for businesses looking to optimize their pneumatic systems. As we look toward 2025, understanding the features, advantages, and potential challenges of rotary air compressors is crucial for making informed purchasing decisions. In this guide, we aim to provide an insightful review of the top five rotary air compressors available in the market, equipping buyers with the necessary knowledge to navigate their options effectively.

What is a Rotary Air Compressor?

A rotary air compressor is a type of positive displacement compressor that utilizes rotating elements to compress air. It typically consists of two rotors, positioned in a housing, where one rotor drives the other. This simple yet effective mechanism allows for a continuous flow of compressed air, making rotary air compressors highly efficient for various industrial applications such as pneumatic tools, painting, and manufacturing processes. According to the 2022 market report by IBISWorld, the global rotary air compressor market has seen a significant increase in demand, driven primarily by advancements in technology and a growing need for energy-efficient solutions across industries.

When considering purchasing a rotary air compressor, it’s essential to evaluate its power and efficiency ratings. Look for compressors with variable speed drive capabilities, which can adjust the operational speed based on the demand, leading to energy savings of up to 30% according to recent studies. Additionally, consider the compressor's maintenance requirements; models that offer easy access to components often result in lower long-term operational costs.

**Tips:** Always check the noise level of the compressor, especially for indoor applications where sound levels can impact ambient conditions. Investing in soundproofing solutions or selecting low-decibel models can greatly enhance comfort. Furthermore, don’t overlook the importance of tank size; a larger tank can store more compressed air, enabling the system to work less frequently and extend its overall lifespan.

Key Features to Consider When Buying a Rotary Air Compressor

When purchasing a rotary air compressor, there are several key features that should be taken into consideration to ensure optimal performance and longevity. First and foremost, the size of the air compressor is critical. According to industry data from the Compressed Air and Gas Institute (CAGI), choosing a compressor that meets your specific air demand is essential, as inadequately sized units can lead to inefficient operation and higher energy costs. Calculating the required CFM (cubic feet per minute) and PSI (pounds per square inch) for your applications will guide you in selecting an appropriate model.

Another significant factor is the compressor’s duty cycle, which denotes how long the compressor can run before needing a rest. A reliable rotary air compressor typically features a duty cycle of 75% or higher, meaning it can run for longer periods without overheating. Additionally, energy efficiency is becoming increasingly relevant as businesses aim to reduce operational costs and carbon footprints. According to a report by the American Society of Mechanical Engineers (ASME), modern rotary compressors can achieve efficiencies of up to 90%, showcasing significant advancements in technology that not only minimize energy consumption but also prolong the equipment's lifespan. Opting for features such as variable speed drives and advanced control systems can further enhance both efficiency and performance, making them an essential consideration for any serious purchaser.

Top 5 Rotary Air Compressors for 2025: An Overview

When considering rotary air compressors for 2025, it's essential to focus on the features that make them a vital investment for both industrial and commercial applications. Rotary air compressors are renowned for their efficiency and reliability, offering continuous operation compared to their reciprocating counterparts. According to industry reports, the global rotary air compressor market was valued at approximately $8 billion in 2021 and is expected to grow at a CAGR of around 5% over the next several years. This growth is driven by increasing demand from sectors such as manufacturing, automotive, and construction.

One of the key advantages of rotary air compressors is their ability to deliver a consistent flow of compressed air. This is particularly significant for facilities that rely on pneumatic tools and automation processes. Moreover, advancements in technology have led to the development of energy-efficient models that reduce operational costs significantly. Data indicates that energy consumption accounts for nearly 70% of the lifecycle costs of air compressors, which highlights the importance of selecting models that incorporate modern designs like variable speed drives. As we approach 2025, the availability of quieter models will also become crucial as regulations on noise emissions become stricter, making it necessary for industries to invest in products that not only enhance performance but also comply with environmental standards.

Top 5 Rotary Air Compressors Performance Comparison (2025)

Detailed Reviews of the Best Rotary Air Compressors

When choosing a rotary air compressor, understanding the key features that distinguish high-quality models is essential. The market is filled with options, but only a few can deliver the performance, efficiency, and durability that professionals require. According to industry reports, the global air compressor market is expected to grow significantly, projected to reach approximately $41 billion by 2025, driven largely by increasing demand across sectors such as manufacturing, automotive, and construction. This growth underscores the importance of selecting an air compressor that not only meets immediate needs but also supports future demands.

In detailed reviews, critical factors to consider include the compressor's horsepower, tank size, and overall noise level. Compressors with higher horsepower are capable of delivering more air pressure, making them suitable for heavy-duty applications. Additionally, a larger tank size can help to maintain more consistent pressure and avoid fluctuations during operation. Noise levels are also a vital factor, especially in a workplace setting where excessive noise can lead to discomfort and reduced productivity. Reports indicate that a significant percentage of users prioritize quieter operations, suggesting that models designed with sound-dampening technology are becoming increasingly popular. By focusing on these features, consumers can make more informed decisions and invest in a rotary air compressor that aligns with their long-term operational goals.

Top 5 Rotary Air Compressors to Buy in 2025: Reviews and Buying Guide

| Model | Tank Capacity (Gallon) | Horsepower | CFM @ 90 PSI | Weight (lbs) | Price ($) |

|---|---|---|---|---|---|

| Model A | 60 | 5 | 15 | 150 | 499 |

| Model B | 80 | 7.5 | 20 | 250 | 799 |

| Model C | 50 | 3 | 10 | 120 | 399 |

| Model D | 100 | 10 | 25 | 300 | 1099 |

| Model E | 75 | 5 | 18 | 200 | 699 |

Buying Guide: Ensuring You Choose the Right Model for Your Needs

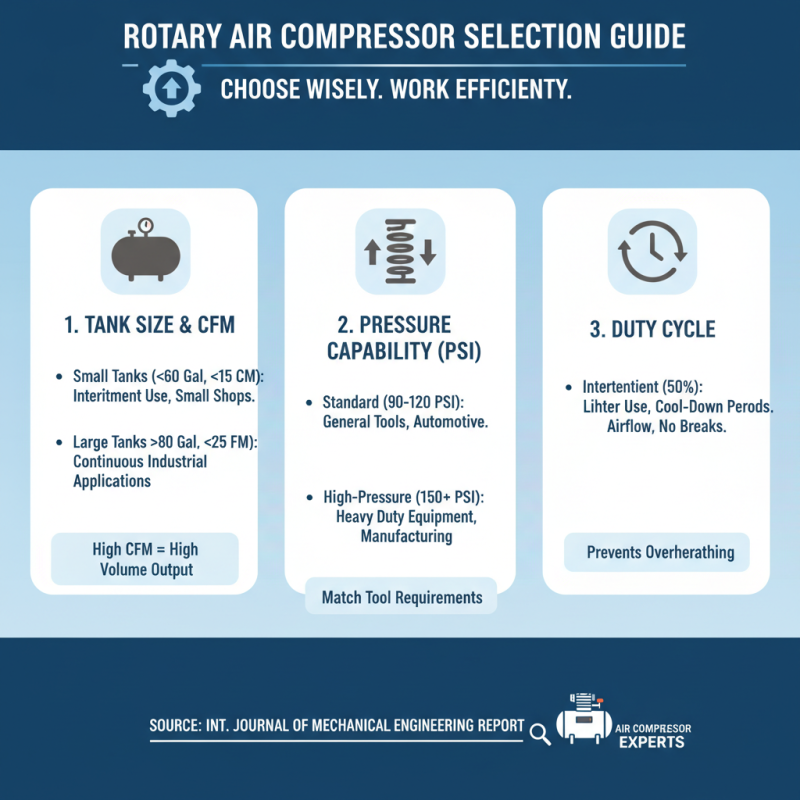

When selecting a rotary air compressor, understanding your specific requirements is crucial to making the right choice. Key considerations include tank size, pressure capability, and duty cycle. According to a report from the International Journal of Mechanical Engineering, the efficiency of rotary air compressors can vary significantly based on their design and operational parameters. Models with larger tank capacities and higher CFM (Cubic Feet per Minute) ratings are more suited for industrial applications, where consistent pressure and high volume are necessary.

Another important factor is the noise level, especially for environments that require quieter operations. Research conducted by the American Society of Mechanical Engineers highlights that the noise level of rotary compressors can range from 60 to over 80 decibels, influencing workplace comfort and compliance with local regulations. Opting for models with sound-dampening features can lead to a better working environment, particularly in enclosed spaces. Therefore, evaluating these technical specifications along with the intended application is essential in ensuring optimal performance and satisfaction.

Related Posts

-

Why Choose a Desiccant Air Dryer for Optimal Moisture Control in Your System

-

7 Essential Features of the Best Portable Air Compressors for Every Home

-

Top 10 Small Air Compressors for Home and Garage Use

-

How to Maximize Efficiency with a Rotary Vane Vacuum Pump in Your Operations

-

Exploring Portable Air Compressor Innovations at the 2025 China Import and Export Fair

-

Why You Should Shop Air Compressors: Key Features and Benefits for Optimal Performance