24 Hour Service

24 Hour Service- 800.825.3222

- Now Hiring

- Request A Quote

Blog

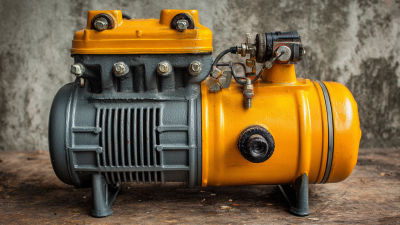

Why You Should Shop Air Compressors: Key Features and Benefits for Optimal Performance

In the ever-evolving landscape of industrial and home improvement tools,

air compressors stand out as versatile powerhouses that can significantly enhance productivity and efficiency.

According to the latest report by the Manufacturing Institute, the air compressor market is expected to grow by

5.2% annually, reaching $40 billion by 2025, reflecting the increasing demand for reliable and high-performance equipment.

As professionals from various sectors seek to maximize their operational capabilities, understanding the significance of choosing the right air compressor becomes paramount.

Expert James Thompson, a leading figure in the air compressor industry, emphasizes,

“Investing in the right air compressor not only boosts output but also enhances the overall quality of work.”To truly unlock optimal performance, it is essential to shop air compressor systems that align with specific needs, whether in automotive repair, construction, or DIY projects. Key features such as tank size, power output, and portability play a critical role in performance, influencing everything from project turnaround times to the longevity of tools being powered. By exploring these aspects, buyers can make informed decisions that ultimately drive efficiency and cost-effectiveness in their operations.

Top Features to Look for in an Air Compressor for Maximum Efficiency

When shopping for an air compressor, understanding the key features that affect performance and efficiency is crucial. One of the top features to consider is the compressor’s CFM (Cubic Feet per Minute) rating, which indicates the volume of air it can deliver. According to a report by the Air Compressor Manufacturers Association, selecting a compressor with an adequate CFM rating can significantly impact the efficiency of your pneumatic tools, ensuring they operate at optimal performance levels.

Another vital feature is the pressure rating, measured in PSI (Pounds per Square Inch). A higher PSI allows for a wider range of applications, from powering nail guns to running sanders and sprayers. Research suggests that compressors with an adjustable PSI setting offer enhanced versatility, allowing users to fine-tune the pressure according to specific needs, ultimately improving productivity.

**Tips:** When choosing an air compressor, consider your primary application to determine the required CFM and PSI. Additionally, look for models with oil-free pumps for easier maintenance and better environmental compliance. Finally, evaluate the tank size to ensure it meets your workload demands, as a larger tank typically provides a steadier airflow for extended use.

Understanding CFM and PSI: The Key Metrics for Optimal Air Compressor Performance

When shopping for an air compressor, understanding CFM (Cubic Feet per Minute) and PSI (Pounds per Square Inch) is essential for making an informed choice. CFM measures the volumetric flow rate of air produced by the compressor. This metric is particularly critical for activities that require a continuous supply of air, such as spray painting or pneumatic tool operation. According to industry standards, a professional-grade air compressor should deliver at least 4 CFM at 90 PSI to effectively power most pneumatic tools, ensuring consistent performance.

On the other hand, PSI indicates the pressure level of the compressed air. For tasks that involve nail guns or high-pressure paint sprayers, a minimum of 90 PSI is typically recommended. As highlighted by reports from the Air Compressors Manufacturers Association, compressors designed for heavy-duty applications can reach up to 175 PSI, allowing them to tackle more demanding jobs with ease. Understanding these two critical metrics will help you evaluate air compressors better and ensure you select one that meets both your performance requirements and efficiency expectations.

The Role of Tank Size in Air Compressor Operation and Longevity

When considering the optimal performance of air compressors, the tank size plays a crucial role in their operation and longevity. According to the Compressed Air and Gas Institute (CAGI), larger tanks can store more compressed air, which reduces the frequency of the compressor cycling on and off. This not only maintains consistent air pressure but also extends the life of the motor and components. For instance, a compressor with a 60-gallon tank operates more efficiently for heavy-duty applications compared to a smaller, 20-gallon model, as it can run longer between cycles without sacrificing performance.

Moreover, tank size directly impacts the compressor's capability to supply air for various tasks. A report from the Industrial Technologies Program indicates that air compressors used in manufacturing environments benefit significantly from larger tank capacities, as they can accommodate higher demands for sustained air pressure. This steady supply is essential for tools such as pneumatic drills or spray guns, which require consistent airflow for optimal operation. Therefore, selecting the right tank size is not merely a matter of preference but a strategic decision that influences overall productivity and machinery lifespan.

Air Compressors: Key Features and Benefits Based on Tank Size

This chart illustrates the optimal performance ratings of air compressors based on tank size, with larger tanks providing higher performance due to their increased storage capacity for compressed air. Small tanks, while portable, tend to deliver lower performance ratings, making medium and large tanks more suitable for demanding tasks.

Electric vs. Gas-Powered Air Compressors: Pros, Cons, and Industry Insights

When it comes to selecting an air compressor, one of the primary considerations is choosing between electric and gas-powered models. According to a report by Gardner Denver, electric air compressors account for approximately 70% of the market, largely due to their efficiency and lower operating costs. These compressors are quieter and require less maintenance than their gas counterparts, making them ideal for indoor use. They are perfect for light to medium-duty tasks, such as powering pneumatic tools in a garage or workshop.

On the other hand, gas-powered air compressors are preferred for heavy-duty applications, particularly in construction sites or remote locations where electricity may not be readily available. A study from the Association of Equipment Manufacturers indicates that while gas compressors offer greater mobility and power output, they have higher fuel costs and emissions. With advancements in technology, newer models are designed to reduce noise and improve fuel efficiency, making them a more viable option for contractors who need both power and portability.

Ultimately, the choice between electric and gas-powered air compressors depends on the specific requirements of the job and the environment in which they will be used.

Maintenance Tips to Enhance the Performance and Lifespan of Your Air Compressor

Regular maintenance of air compressors is essential for ensuring their optimal performance and longevity. According to a report by the Industrial Technology Institute, 80% of compressor failures are due to inadequate maintenance practices. Simple steps like changing the oil at recommended intervals, typically every 500 to 1,000 hours of operation, can significantly extend the lifespan of your unit. Regularly checking and replacing air filters also enhances airflow, which is critical for maintaining efficiency. A clean air filter can improve compressor efficiency by up to 10%, as stated in a study by the American Society of Mechanical Engineers.

Incorporating periodic inspections into your maintenance routine is equally vital. This includes checking for leaks, ensuring belts are well tensioned, and verifying proper functioning of safety valves. The National Institute for Occupational Safety and Health indicates that regular maintenance reduces energy consumption by approximately 20%, leading to substantial cost savings over time. Furthermore, an effectively maintained air compressor can operate efficiently under varying conditions, adapting swiftly to changes in demand without excessive strain on its components. By prioritizing these maintenance tips, users can enhance the performance and reliability of their compressors, ensuring they serve effectively for many years.

Related Posts

-

Real World Applications of Rotary Screw Air Compressors in Various Industries

-

Understanding the Mechanisms Behind Electric Air Compressors: A Deep Dive into Their Functionality

-

Exploring Portable Air Compressor Innovations at the 2025 China Import and Export Fair

-

Maximize Efficiency: How a Gas Air Compressor Transforms Your Workshop Experience

-

Expert Guide to Affordable Air Compressor Repair Techniques for Homeowners

-

Desiccant Air Dryer Showdown: Which Option Delivers the Best Performance for Your Needs?