24 Hour Service

24 Hour Service- 800.825.3222

- Now Hiring

- Request A Quote

Blog

Revolutionizing Industrial Cleaning: How Air Knife Blowers Increase Efficiency by 30% Over Traditional Methods

In the realm of industrial cleaning, efficiency is paramount, and one innovative solution is capturing the attention of manufacturers worldwide: the air knife blower.

Traditional cleaning methods often struggle with effectiveness and time consumption, leading to increased operational costs and downtime. However, the air knife blower revolutionizes this process by providing a powerful, precise stream of high-velocity air that effectively removes contaminants from surfaces.

This transformative technology not only accelerates the cleaning process but has been shown to achieve an impressive 30% increase in efficiency compared to conventional methods.

In this guide, we will explore how air knife blowers work, the advantages they offer, and how implementing this cutting-edge equipment can streamline industrial cleaning operations, ultimately driving productivity and cost savings in today’s competitive landscape.

Understanding the Basics: What Are Air Knife Blowers and How Do They Work?

Air knife blowers are an innovative solution in the industrial cleaning sector, designed to efficiently remove contaminants from surfaces without the need for traditional cleaning methods. Utilizing a high-velocity jet of air, these devices create a thin, controlled sheet of air that effectively displaces dust, moisture, and debris. According to a recent report by the Clean Industries Institute, air knife blowers can reduce cleaning time by up to 30%, a significant improvement over conventional methods such as manual wiping or pressure washing.

The operation of air knife blowers is based on Bernoulli's principle, where the fast-moving air creates a low-pressure zone that pulls contaminants away from the surface. This technology not only increases efficiency but also minimizes water usage and the need for chemical agents, promoting a more sustainable approach to industrial cleaning. The Institute of Industrial Technology highlights that businesses utilizing air knife blowers can expect operational costs to decrease by approximately 25% due to lower water and material consumption, making it a financially viable option for companies looking to optimize their cleaning processes.

Comparative Analysis: Air Knife Blowers vs. Traditional Industrial Cleaning Methods

In the realm of industrial cleaning, the comparison between air knife blowers and traditional cleaning methods reveals significant advantages for the former. Air knife blowers utilize high-velocity air streams to displace contaminants effectively, offering a distinct edge in efficiency. Traditional methods, such as using brushes or cloths, often require numerous manual steps that can lead to inconsistent results and increased labor costs. By contrast, air knife blowers streamline the cleaning process, allowing operators to achieve optimal cleanliness with reduced effort and time.

Moreover, the operational costs associated with air knife blowers are generally lower over time. While the initial investment may be higher, the reduction in labor hours and the impressive energy efficiency they provide lead to considerable savings. Traditional cleaning methods often consume more resources, contributing to higher costs in materials and worse environmental impact due to increased waste. The comparative analysis clearly demonstrates that air knife blowers not only enhance cleaning efficacy but also represent a forward-thinking solution aimed at improving overall productivity in industrial settings.

Key Efficiency Metrics: Evaluating the 30% Increase in Cleaning Speed with Air Knife Technology

The advent of air knife technology is reshaping the landscape of industrial cleaning by promising a significant boost in efficiency. Recent studies indicate that air knife blowers can enhance cleaning speeds by up to 30% compared to traditional methods, reflecting a profound shift in operational performance. According to a report by the Cleaning Industry Research Institute, conventional cleaning techniques often involve manual labor and conventional drying methods, which can be labor-intensive and time-consuming. In contrast, air knife systems utilize high-velocity air streams to displace contaminants swiftly, drastically reducing both cleaning time and labor costs.

Key efficiency metrics demonstrate that facilities employing air knife technology see not only improved speed but also enhanced thoroughness in cleaning processes. A case study published by the Association for Cleaning Professionals noted that companies leveraging air knives experience a 50% reduction in drying time and a decrease in water usage by nearly 40%. This combination of factors leads to greater overall productivity, allowing businesses to allocate resources more effectively. As industries continue to prioritize efficiency, air knife blowers stand out as a reliable solution for modern cleaning challenges.

Cost-Benefit Considerations: Long-Term Savings Using Air Knife Blowers in Industry

The implementation of air knife blowers in industrial cleaning processes offers significant long-term savings compared to traditional methods. While the initial investment in these advanced systems may seem higher, the cost-benefit analysis quickly tilts in favor of air knife technology. These blowers optimize air flow to remove moisture and debris efficiently, reducing energy consumption and labor costs associated with manual cleaning.

Tips for maximizing cost-effectiveness include regularly maintaining your air knife blowers to ensure they operate at peak efficiency and training employees to use them correctly. Additionally, considering the integration of air knife systems during the design phase of manufacturing processes can lead to more streamlined operations, resulting in further savings down the line.

In the long run, using air knife blowers not only enhances efficiency by up to 30% but also minimizes downtime. This boost in productivity translates to lower operational costs, making the investment worthwhile for industries looking to improve their cleaning protocols and overall performance. By adopting air knife technology, companies can focus more on their core activities while benefiting from cleaner, safer working environments.

Efficiency Comparison: Air Knife Blowers vs Traditional Methods

This chart illustrates the efficiency improvement achieved by using air knife blowers in industrial cleaning compared to traditional methods. The data indicates a 30% increase in efficiency when adopting air knife blowers, leading to significant long-term savings.

Real-World Applications: Successful Case Studies of Air Knife Implementations in Various Industries

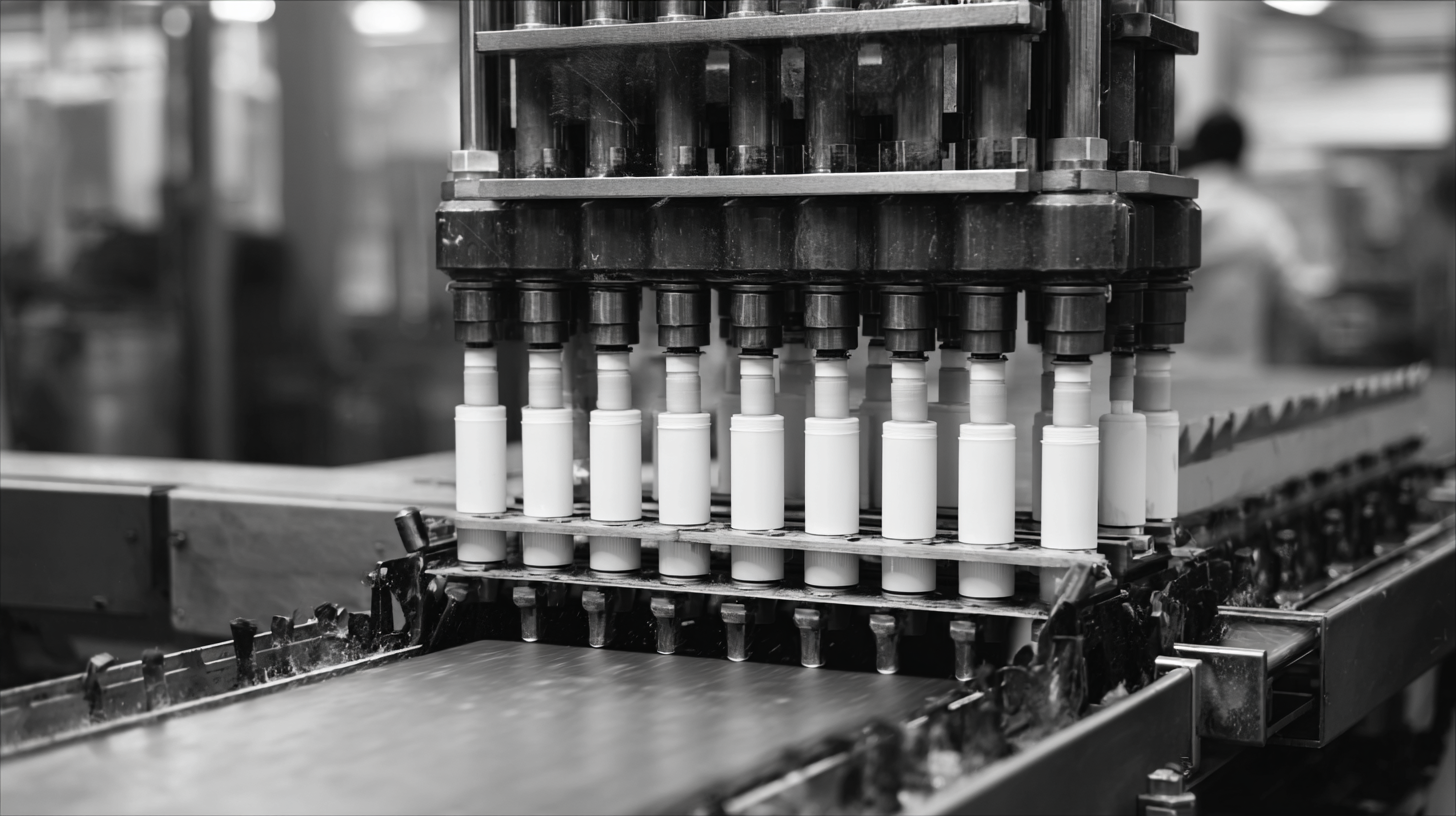

Air knife blowers are transforming industrial cleaning processes, showcasing remarkable efficiency improvements across various sectors. For instance, in the food and beverage industry, a leading manufacturer implemented air knives to dry freshly washed bottles before labeling. This transition not only reduced drying time by nearly half but also eliminated water spots, enhancing product quality. The air knife technology, delivering focused jets of air, ensures thorough cleanliness without the use of excessive water or chemicals, making it an eco-friendly solution.

In the automotive sector, a car assembly plant integrated air knife blowers into its cleaning operations to remove debris and dust from vehicle surfaces. The result was a 30% enhancement in cleaning efficiency compared to traditional methods. This case study illustrates that the precise blowing action of air knives can effectively streamline production processes, reduce labor costs, and improve overall operational productivity. These implementations highlight the versatility of air knife technology, proving beneficial across diverse industries by not only maintaining high cleanliness standards but also contributing to sustainability efforts.

Related Posts

-

What is a Small Air Compressor and How Can It Benefit Your Business

-

Desiccant Air Dryer Showdown: Which Option Delivers the Best Performance for Your Needs?

-

Maximize Efficiency: How a Gas Air Compressor Transforms Your Workshop Experience

-

Navigating the 2025 Landscape of Best Rotary Screw Compressors and Their Impact on Global Procurement

-

Ultimate Guide to Choosing the Best Scroll Air Compressor for Your Business Needs

-

Ultimate Guide to Understanding Air Compressor Parts for Optimal Performance