24 Hour Service

24 Hour Service- 800.825.3222

- Now Hiring

- Request A Quote

Blog

What is a Nitrogen Generator and How Does It Work?

The use of nitrogen generators has gained traction across various industries in recent years. According to a report by Markets and Markets, the nitrogen generator market is projected to reach $5.4 billion by 2025, reflecting an increasing demand for efficient gas solutions. These devices produce nitrogen on-site, which reduces dependency on bottled gas and lowers operational costs significantly.

Dr. Amy Thompson, an industry expert, notes, "The evolution of nitrogen generators has revolutionized how businesses approach gas management." This highlights the value these systems bring. With a nitrogen generator, companies can enhance productivity and ensure a consistent nitrogen supply. However, challenges remain. Some organizations struggle to adapt to the technology due to initial setup costs and understanding the system’s workings.

Understanding these machines requires consideration of both their advantages and potential limitations. Companies must weigh costs against the long-term benefits. The nitrogen generator landscape is evolving, yet there is still room for improvement in adoption rates and user knowledge. The journey to maximizing efficiency with nitrogen generators continues.

What is a Nitrogen Generator?

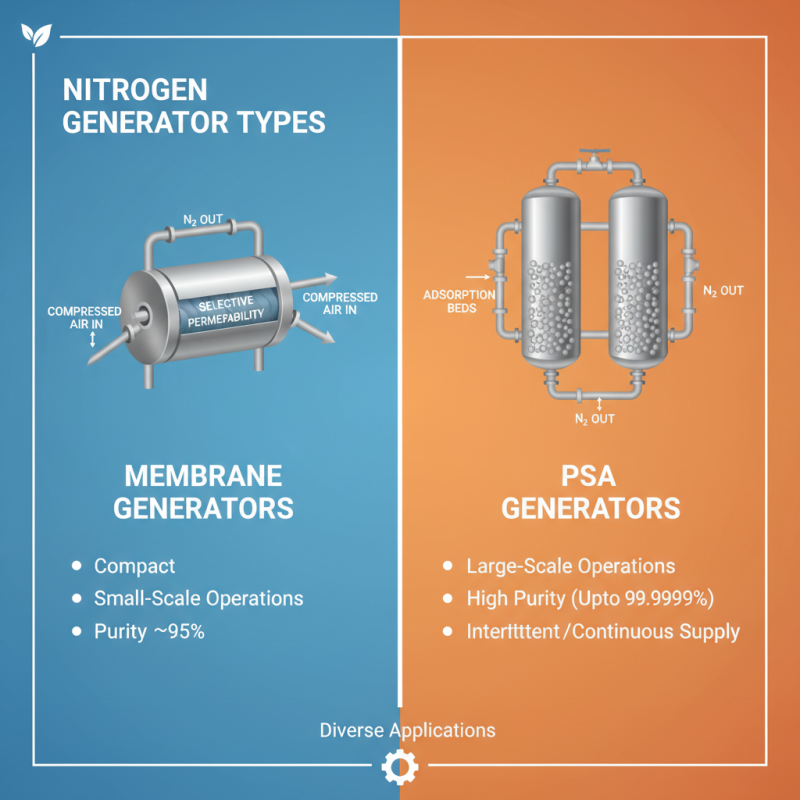

A nitrogen generator is a device that produces nitrogen on-site. It does this by separating nitrogen from other gases in the air. The process usually involves two methods: membrane separation and pressure swing adsorption (PSA). Both methods are effective but have their unique characteristics.

In membrane separation, air is pushed through a series of filters. These filters allow nitrogen to pass through while trapping other gases like oxygen. The result is a stream of purified nitrogen. On the other hand, PSA uses specially designed adsorbent materials. These materials capture oxygen and other gases, releasing high-purity nitrogen. The two approaches provide flexibility for various applications.

This technology has its drawbacks. Installation can be complex. Maintenance requires skilled technicians. Users must also monitor purity levels regularly. Over time, efficiency may decline without proper care. Understanding these factors helps users make informed decisions about nitrogen generators.

Nitrogen Generator Efficiency by Type

This chart illustrates the efficiency percentages of various types of nitrogen generators. Membrane technology operates at around 90% efficiency, PSA technology offers the highest efficiency at 95%, while LN2 regeneration has an efficiency of about 85%.

The Principle of Nitrogen Generation Technology

Nitrogen generation technology operates on key principles that ensure efficient production. A nitrogen generator typically separates nitrogen from air using two primary methods: membrane separation and pressure swing adsorption (PSA). The PSA method takes advantage of the different adsorption rates of gases under high pressure. As compressed air passes through adsorbent materials, nitrogen molecules flow freely while oxygen and other impurities are captured.

Recent reports indicate that nitrogen makes up about 78% of the Earth's atmosphere. This abundant resource provides a cost-effective route for industrial applications. For example, in the oil and gas industry, nitrogen is critical for inerting and purging processes. Using nitrogen generators can significantly reduce dependency on liquid nitrogen, cutting operational costs by up to 50%.

The technology is not without challenges. Maintaining consistent nitrogen purity levels can be tricky, especially in low-demand scenarios. Additionally, the energy consumption of generators can be substantial. Balancing efficiency with the environmental impact is an ongoing concern in the field. Despite these hurdles, advancements in technology are making nitrogen production increasingly feasible and resource-efficient.

Types of Nitrogen Generators and Their Applications

Nitrogen generators come in various types, each serving distinct applications. The two primary types are membrane nitrogen generators and PSA (Pressure Swing Adsorption) nitrogen generators. Membrane generators separate nitrogen from compressed air using selective permeability. They are compact and suitable for small-scale operations, typically producing nitrogen with purity levels around 95%.

PSA nitrogen generators, on the other hand, utilize a two-tower system to achieve higher purity levels, often exceeding 99%. This technology is versatile, widely used in industries such as pharmaceuticals and food packaging. According to industry reports, the demand for high-purity nitrogen in food processing has surged by 15% in recent years. This trend showcases the increasing need for efficient and reliable nitrogen supply solutions.

Applications vary significantly. Nitrogen is essential in the electronics sector for preventing oxidation during manufacturing. In the chemical industry, it acts as an inert gas to ensure safe reactions. However, some companies still rely on gas cylinders, leading to increased operational costs and safety risks. As nitrogen generator technology evolves, a shift towards a more sustainable and cost-effective approach is necessary. Balancing efficiency and safety must remain a priority in future developments.

How Nitrogen Generators Work: A Step-by-Step Process

Nitrogen generators are innovative systems used to produce nitrogen gas for various applications. They operate on a straightforward principle known as pressure swing adsorption (PSA). The process begins with atmospheric air being drawn into the generator. This air consists of about 78% nitrogen and 21% oxygen. The separation of these gases happens in a series of steps.

In the first stage, the air enters the adsorber where a special material captures the oxygen. The nitrogen moves through while the oxygen gets trapped. After the adsorber reaches its capacity, it undergoes regeneration. This phase involves reducing the pressure, which releases the trapped oxygen back into the atmosphere. Meanwhile, fresh air fills the adsorber, starting the cycle anew.

The generator produces steady nitrogen flow, but it’s not without flaws. Sometimes, the adsorption material can become less effective over time. Regular maintenance is necessary to ensure consistent performance. Additionally, environmental conditions like humidity can impact the process. Understanding these factors is crucial for optimal operation. Nitrogen generators offer a reliable gas source, yet users must remain vigilant about monitoring and adjustments.

What is a Nitrogen Generator and How Does It Work?

| Dimension | Description | Value |

|---|---|---|

| Purity Level | Percentage of Nitrogen produced | 95% - 99.999% |

| Production Rate | Amount of nitrogen produced per hour | 5 NM³/h - 500 NM³/h |

| Technology Used | Method applied for nitrogen generation | PSA (Pressure Swing Adsorption) |

| Key Components | Main parts of a nitrogen generator | Air compressor, Adsorption unit, Control system |

| Applications | Industries using nitrogen generators | Food packaging, Electronics, Pharmaceuticals |

| Cost Efficiency | Comparison of nitrogen generation costs | Reduces costs by 50% compared to cylinder supply |

Advantages of Using Nitrogen Generators in Industry

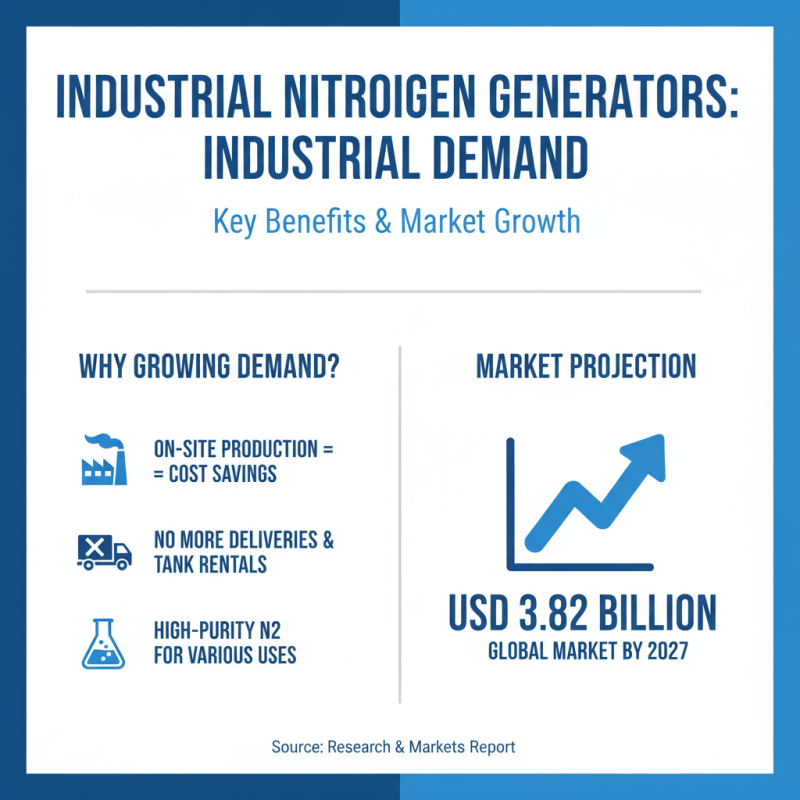

Nitrogen generators are increasingly vital in various industries due to their ability to produce high-purity nitrogen on-site. This reduces the need for costly deliveries and tank storage. A report from Research and Markets states that the global nitrogen gas generator market is projected to reach USD 3.82 billion by 2027. Clearly, there is a growing demand for this technology.

Using nitrogen generators offers significant advantages. For instance, they enhance safety by reducing reliance on high-pressure gas cylinders. Industries such as pharmaceuticals benefit from stable nitrogen supplies, ensuring product integrity. Nitrogen is essential for preserving sensitive materials during packaging and transportation. The deployment of these generators can lead to substantial cost savings, with some organizations reporting reductions of up to 30% in gas expenses.

However, implementing nitrogen generation systems is not without challenges. Initial installation costs can be high and may require a dedicated maintenance team. Many companies struggle with optimizing their systems to meet varying nitrogen demands. Regular monitoring and adjustments are crucial. A general lack of knowledge about proper operation can lead to inefficiencies. Each industry must weigh these challenges against the long-term benefits.

Related Posts

-

Real World Applications of Rotary Screw Air Compressors in Various Industries

-

Why Do You Need an Air Compressor Water Separator?

-

Expert Guide to Affordable Air Compressor Repair Techniques for Homeowners

-

Top 10 Small Air Compressors for Home and Garage Use

-

Top 10 Essential Air Compressor Parts You Need for Optimal Performance

-

Ultimate Guide to Understanding Air Compressor Parts for Optimal Performance