24 Hour Service

24 Hour Service- 800.825.3222

- Now Hiring

- Request A Quote

Blog

Why Do You Need an Air Compressor Water Separator?

In the world of industrial machinery, the role of an air compressor water separator is often underestimated. Renowned expert in pneumatic systems, Dr. Emily Carter, emphasizes its importance by stating, "Ignoring moisture in compressed air systems can lead to severe damage." This reveals a critical issue many face.

Air is not just air; it carries moisture that can create problems in compressors. A water separator effectively removes this moisture, protecting your equipment. Without it, rust and corrosion can form, leading to expensive repairs.

The implementation of an air compressor water separator is not merely best practice—it's essential. Users often overlook how inadequate moisture management can reduce efficiency and lifespan. It's time to reflect on whether you are prioritizing proper moisture control in your air systems.

Understanding the Function of an Air Compressor Water Separator

Air compressor water separators play a crucial role in maintaining air quality. When air is compressed, moisture often condenses. This moisture can cause several issues in pneumatic systems. Therefore, a water separator is designed to extract this excess water. By removing water, it helps prevent rust and corrosion in tools and equipment.

The function of an air compressor water separator is relatively straightforward. It typically uses gravity or coalescing technology to capture water droplets. As air flows through the separator, heavier water particles settle down. What remains is cleaner, dryer air. This process is vital in many industries, from automotive to construction.

However, some users overlook the importance of regular maintenance. A dirty or clogged separator can become ineffective. It may lead to compromised air quality, affecting performance. Users need to monitor the separator regularly. This reflection can save both time and resources, ensuring optimal function in the long run.

Why Do You Need an Air Compressor Water Separator? - Understanding the Function of an Air Compressor Water Separator

| Feature | Description | Benefits |

|---|---|---|

| Condensation Removal | Separates water vapor from compressed air. | Prevents moisture-related damage to tools and equipment. |

| Improved Air Quality | Reduces water contaminants in the air stream. | Enhances the reliability and performance of pneumatic systems. |

| Efficiency Boost | Maintains optimal operating conditions by controlling moisture. | Increases the lifespan of the compressor and minimizes downtime. |

| Versatile Application | Suitable for various industries including automotive, manufacturing, and HVAC. | Broadens the range of applications for compressed air systems. |

| Ease of Maintenance | Designed for simple cleaning and maintenance protocols. | Saves time and costs associated with upkeep. |

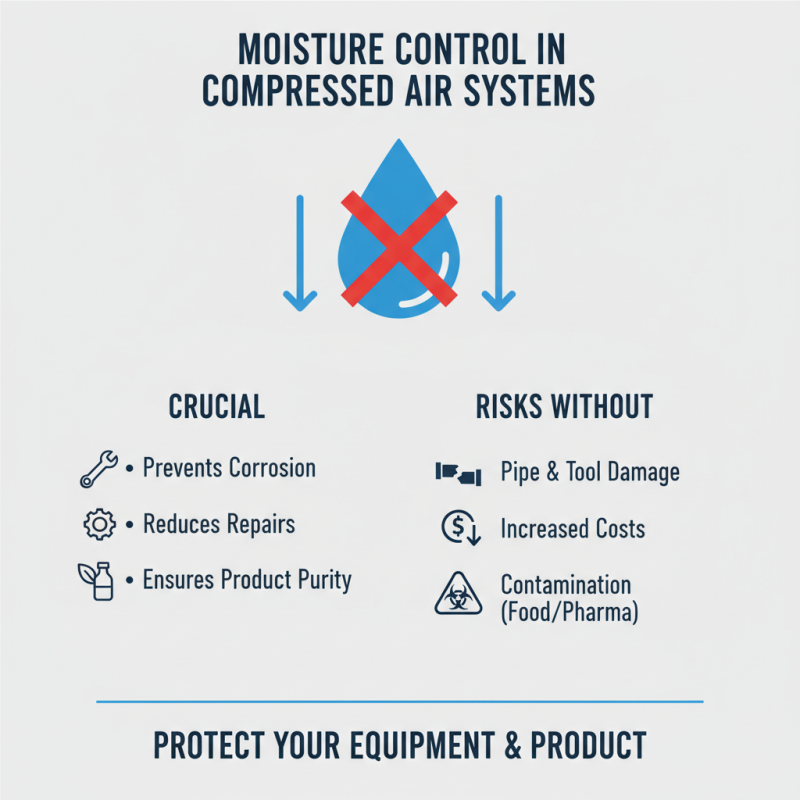

The Importance of Moisture Control in Compressed Air Systems

Moisture control in compressed air systems is crucial. Without proper management, issues arise. Water can corrode pipes and tools, leading to costly repairs. It can also cause product contamination, especially in industries like food and pharmaceuticals.

An air compressor water separator helps eliminate moisture in the air supply. That way, compressed air remains clean and dry. It acts as a barrier, trapping water droplets before they reach the end user. However, it isn’t perfect. Some moisture may still pass through. Regular maintenance is necessary to ensure efficiency.

Inaccurate moisture control can lead to significant problems. Equipment might fail unexpectedly. Production processes could be disrupted. Operators must consistently monitor moisture levels. This proactive approach avoids potential disasters and maintains productivity. Embracing good moisture management practices can save time and money in the long run. A balanced system ensures a smooth operation, where every component functions optimally.

How an Air Compressor Water Separator Works

An air compressor water separator is crucial in any compressed air system. It removes moisture before it enters the lines. Moisture can lead to rust and damage. Thus, it protects tools and equipment. Poor air quality can cause issues. An effective separator helps maintain a consistent flow.

The separator works by utilizing gravity and coalescing filters. Moist air enters and cools down. Water droplets gather and fall into a tank. Filters capture tiny water particles. This two-step process enhances air quality. Users often miss maintenance tasks. An unchecked separator can reduce efficiency. Regular checks can help maximize performance.

Another aspect to consider is the separator's placement. Position affects its efficiency significantly. Installing it too far may lead to water accumulation. Not enough attention to position can harm overall operations. A thoughtful setup yields better results.

Common Applications for Air Compressor Water Separators

Air compressor water separators play a crucial role in a variety of applications. Many industries rely on compressed air for their operations. However, moisture in compressed air can lead to significant issues. Water droplets can corrode equipment, reduce efficiency, and contaminate products. This is where water separators come in.

In automotive service centers, they help maintain air quality. When air tools are used, water can hinder performance. A water separator ensures that tools work smoothly. Moreover, in painting and finishing processes, eliminating moisture is vital. Even a tiny amount of water can ruin a finish. A simple misstep can lead to costly reworks.

Manufacturing operations also benefit greatly. Water separators keep pneumatic systems running efficiently. In food processing, they ensure air used is clean and dry. Contaminated air can jeopardize food safety. These examples highlight the importance of maintaining air quality, yet many overlook this. Regular maintenance of separators is necessary, but it is often neglected. This oversight can lead to increased downtime and costs.

Maintenance Tips for Ensuring Optimal Performance of Water Separators

Maintaining air compressor water separators is essential. These devices prevent moisture from damaging your air tools. Regular inspection can save costs and headaches later.

Check the separator weekly. Look for signs of wear or corrosion. Empty the water trap as needed. This helps ensure proper function. Neglecting this task could lead to water buildup. That accumulation can affect air quality and equipment lifespan. Occasionally, the separator might not work optimally. This could result from dirt or debris clogging the filter.

Cleaning the separator should be part of your routine. Use compressed air to blow out any contaminants. However, avoid high pressures that could cause damage. Make sure to check the seals regularly. A worn seal can lead to leaks and reduced performance. Remember, good maintenance habits lead to more reliable operation.

Related Posts

-

Top 10 Best Refrigerated Air Dryers for Your Industrial Needs

-

Understanding the Challenges Faced by Global Buyers in Sourcing Desiccant Air Dryers

-

Understanding the Impact of Quality Compressor Parts on Industrial Efficiency and Maintenance Costs

-

What is an Air Compressor Water Separator and How Does It Work

-

Top 10 Essential Air Compressor Parts You Need for Optimal Performance

-

How to Choose the Right Refrigerated Air Dryer for Your Needs?