24 Hour Service

24 Hour Service- 800.825.3222

- Now Hiring

- Request A Quote

Blog

How to Maximize Efficiency with a Rotary Vane Vacuum Pump in Your Operations

In today’s fast-paced industrial environment, optimizing operational efficiency is crucial for maintaining competitiveness and profitability. The rotary vane vacuum pump has emerged as a vital component for various applications, including packaging, food processing, and pharmaceuticals. According to a recent report by MarketsandMarkets, the global vacuum pump market is expected to grow from $3.8 billion in 2023 to $5.2 billion by 2028, with rotary vane vacuum pumps playing a significant role in this expansion due to their reliability and efficiency. By maximizing the performance of rotary vane vacuum pumps, businesses can enhance production speeds, reduce downtime, and lower energy consumption, ultimately leading to substantial cost savings. This article will explore effective strategies to leverage the capabilities of rotary vane vacuum pumps to boost overall operational efficiency.

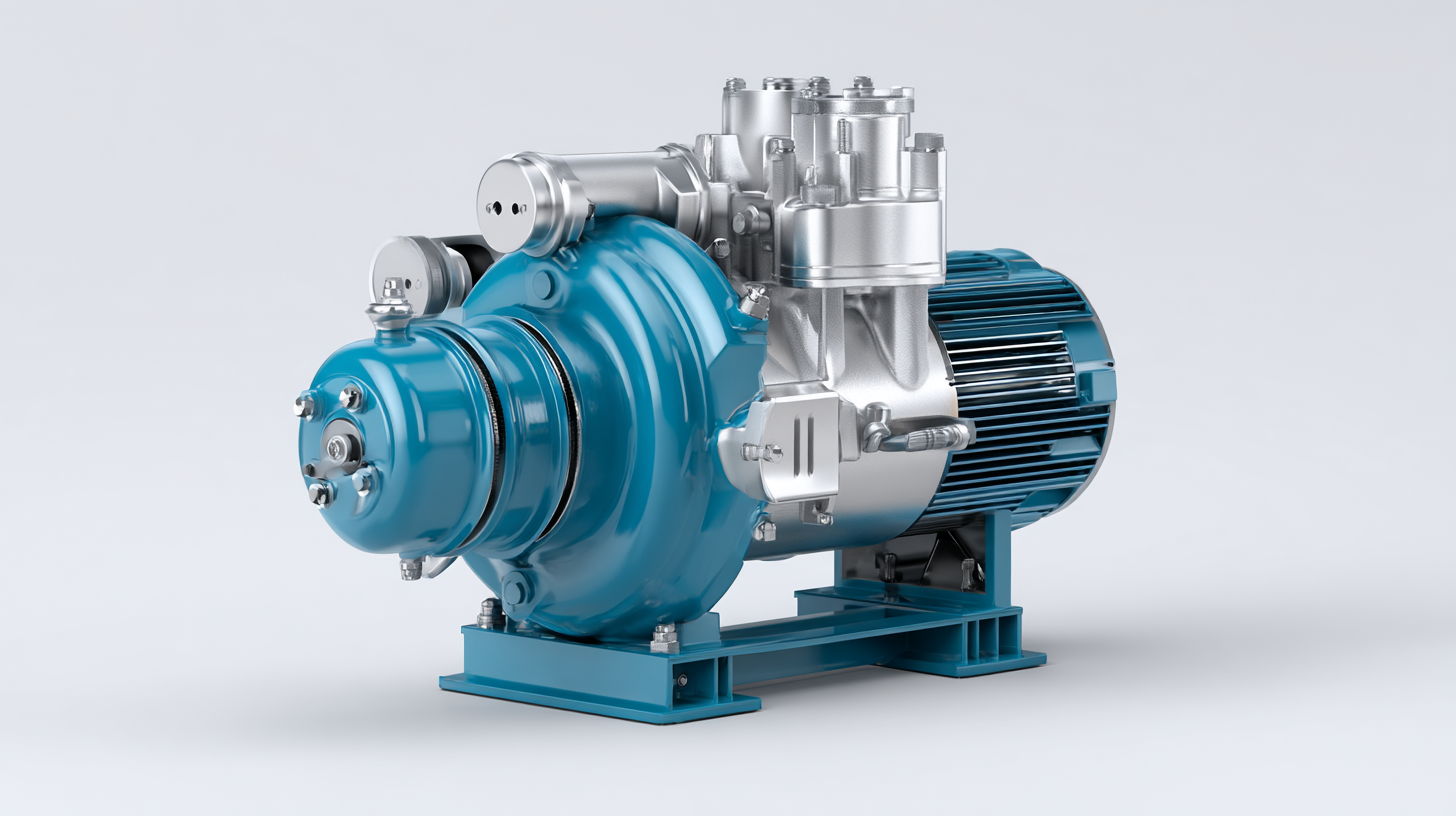

Understanding the Basics of Rotary Vane Vacuum Pumps and Their Applications

Rotary vane vacuum pumps are an essential tool in various industrial applications due to their versatility and efficiency. Functioning through rotating vanes that create vacuum pressure, these pumps are particularly effective in packaging, pharmaceuticals, and food processing sectors. According to a recent report from the International Vacuum Pump Market Analysis, the demand for rotary vane vacuum pumps is expected to grow by 5.2% annually, highlighting their significance in optimizing operational efficiency.

Rotary vane vacuum pumps are an essential tool in various industrial applications due to their versatility and efficiency. Functioning through rotating vanes that create vacuum pressure, these pumps are particularly effective in packaging, pharmaceuticals, and food processing sectors. According to a recent report from the International Vacuum Pump Market Analysis, the demand for rotary vane vacuum pumps is expected to grow by 5.2% annually, highlighting their significance in optimizing operational efficiency.

When utilizing rotary vane vacuum pumps, it’s crucial to understand their operational aspects to maximize effectiveness. Regular maintenance, such as replacing worn vanes and ensuring proper lubrication, is vital for sustaining performance levels. Studies show that scheduled maintenance can improve pump efficiency by up to 30%, reducing overall downtime and lowering costs associated with unexpected repairs.

Tips: To ensure optimal use of your rotary vane vacuum pump, consider monitoring the vacuum pressure regularly to detect any inefficiencies early. Additionally, maintaining an ideal operating environment by controlling temperature and minimizing dust can significantly extend the lifespan of the pump and enhance performance. By implementing these practices, businesses can leverage the full potential of rotary vane technology in their operations.

Identifying Key Efficiency Metrics for Vacuum Pump Operations

To maximize efficiency with a rotary vane vacuum pump, it's crucial to identify and monitor key efficiency metrics. One of the primary metrics to consider is the pump's ultimate vacuum level, which indicates the lowest pressure the pump can achieve. This measurement affects overall system performance and determines the pump's suitability for specific applications. Regular monitoring of this metric can help operations pinpoint issues such as leaks or wear, ensuring that the pump operates at an optimal level.

Another important metric is the pumping speed, which reflects how quickly the vacuum pump can remove gas from a defined space. Evaluating the pumping speed under various operating conditions can reveal the pump's effectiveness in maintaining desired vacuum levels efficiently. Additionally, tracking the energy consumption relative to performance output is essential. By analyzing power usage alongside vacuum levels and speed, businesses can identify opportunities for improving process efficiency, potentially leading to cost savings and enhanced operational effectiveness.

Implementing Maintenance Best Practices to Enhance Pump Performance

To maximize the efficiency of a rotary vane vacuum pump, implementing

best maintenance practices is crucial. According to the

European Vacuum Industry Association (EVIA), proper maintenance can enhance pump performance by up to

20%. Regular checks on oil levels and the condition of the vanes can prevent premature wear

and ensure optimal vacuum levels. This reduces operating costs, as a well-maintained pump consumes less energy,

aligning with data from the U.S. Department of Energy which indicates that efficient systems can save up

to 30% in energy expenses.

Additionally, consistent monitoring and timely replacements extend the life of the vacuum pump. A report from

the Vacuum Technology Association highlights that neglecting maintenance can lead to a

15% decrease in pumping efficiency over time. Establishing a regular maintenance schedule that

includes inspections, cleaning, and replacement of worn parts can help mitigate these risks. Incorporating advanced monitoring

technologies, such as IoT sensors, can further enhance maintenance efforts, allowing for

real-time data analysis and proactive decision-making. By focusing on these best practices, facilities can optimize their operations

and ensure longevity and reliability of their rotary vane vacuum pumps.

Optimizing Vacuum System Design for Maximum Productivity

Optimizing vacuum system design is crucial for maximizing productivity when utilizing rotary vane vacuum pumps in various operations. The efficiency of these systems can be significantly improved by focusing on several key factors, such as proper sizing, ensuring adequate airflow, and maintaining consistent operating temperatures. By selecting the right pump size and configuration, businesses can achieve optimal vacuum levels quickly, reducing downtime and enhancing overall operational efficiency.

Moreover, integrating the rotary vane vacuum pump with advanced control systems can lead to more precise adjustments based on real-time data. This not only minimizes energy consumption but also extends the lifespan of the equipment. The increasing adoption of innovative technologies, such as artificial intelligence and sophisticated monitoring systems, enables organizations to streamline their processes, achieve better performance metrics, and foster a culture of continuous improvement. By prioritizing these aspects in vacuum system design, companies can enhance their production capabilities and respond effectively to market demands.

Troubleshooting Common Issues to Maintain Operational Efficiency

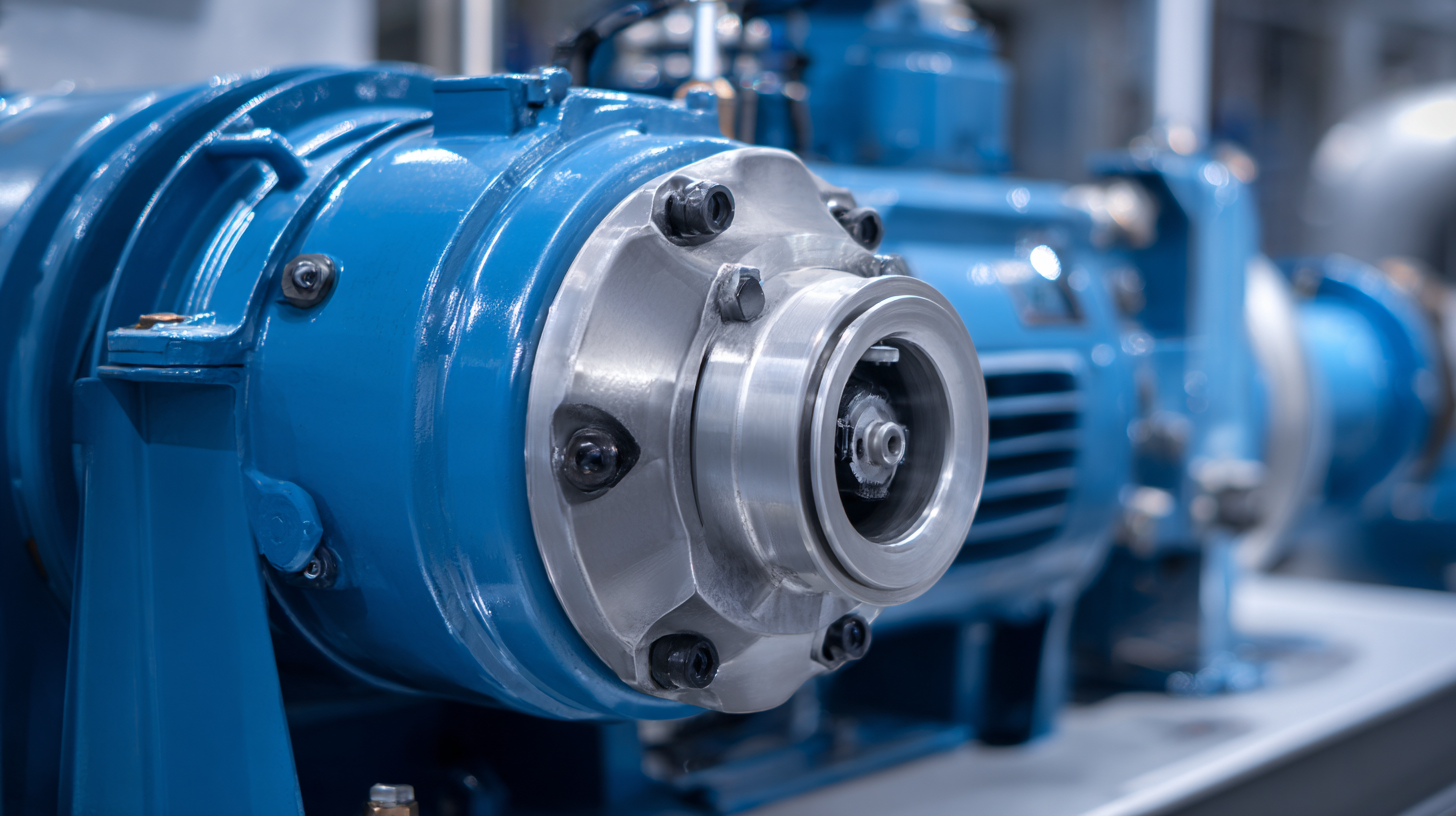

When operating a rotary vane vacuum pump, maintaining its efficiency is crucial for optimal performance. One common issue that may arise is inadequate vacuum pressure. This can often be traced back to worn or damaged vanes. Regular inspections and timely replacements of the vanes help ensure that the pump maintains the necessary pressure levels for your operations. Additionally, checking for air leaks in the system can prevent loss of vacuum and enhance the overall efficiency of the pump.

Another frequent problem is overheating, which can significantly impact the longevity of the vacuum pump. Overheating typically results from insufficient lubrication or a blocked exhaust filter. It’s essential to monitor the oil levels and replace oil as necessary, while also ensuring that the exhaust filter is clean and unobstructed. By addressing these issues promptly, operators can minimize downtime and maintain the effectiveness of the rotary vane vacuum pump in their processes. Regular maintenance and troubleshooting practices can lead to improved operational efficiency, prolonging the lifespan of the equipment.

Maximizing Efficiency with a Rotary Vane Vacuum Pump

This chart illustrates the common operational issues encountered with rotary vane vacuum pumps and their respective impact on efficiency. By identifying and addressing these issues, organizations can maintain optimal performance.

Related Posts

-

Navigating the 2025 Landscape of Best Rotary Screw Compressors and Their Impact on Global Procurement

-

Understanding the Challenges Faced by Global Buyers in Sourcing Desiccant Air Dryers

-

Real World Applications of Rotary Screw Air Compressors in Various Industries

-

7 Essential Tips for Choosing the Best Oil Free Air Compressor

-

What is a Small Air Compressor and How Can It Benefit Your Business

-

Understanding the Mechanisms Behind Electric Air Compressors: A Deep Dive into Their Functionality