24 Hour Service

24 Hour Service- 800.825.3222

- Now Hiring

- Request A Quote

Blog

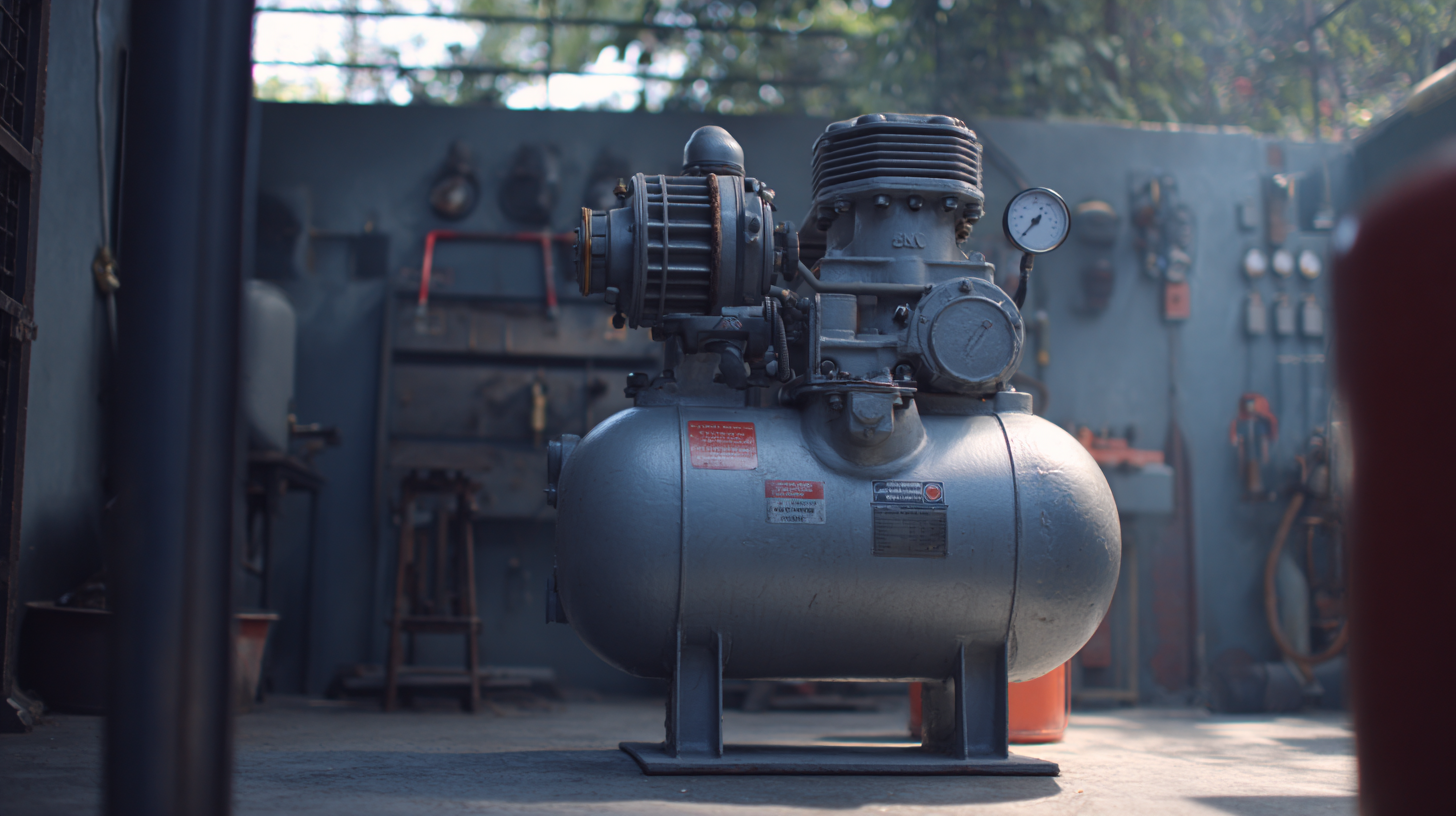

Maximize Efficiency: How a Gas Air Compressor Transforms Your Workshop Experience

The workshop landscape is evolving, with efficiency at the forefront of modern tool usage. A gas air compressor stands out as a pivotal asset for enhancing productivity in various industries. According to a recent report by MarketsandMarkets, the global compressor market is projected to reach $41.5 billion by 2026, largely driven by the demand for advanced pneumatic systems. As businesses strive for optimal performance, gas air compressors offer a powerful solution, delivering consistent and high-pressure air for a wide range of applications, from small-scale workshops to large manufacturing facilities. With their ability to operate without the constraints of electrical outlets, gas air compressors enable greater mobility and flexibility, transforming the traditional workshop experience into one marked by increased efficiency and reduced downtime. Embracing this technology not only enhances operational workflows but also positions workshops to meet the demands of a rapidly changing industrial environment.

The workshop landscape is evolving, with efficiency at the forefront of modern tool usage. A gas air compressor stands out as a pivotal asset for enhancing productivity in various industries. According to a recent report by MarketsandMarkets, the global compressor market is projected to reach $41.5 billion by 2026, largely driven by the demand for advanced pneumatic systems. As businesses strive for optimal performance, gas air compressors offer a powerful solution, delivering consistent and high-pressure air for a wide range of applications, from small-scale workshops to large manufacturing facilities. With their ability to operate without the constraints of electrical outlets, gas air compressors enable greater mobility and flexibility, transforming the traditional workshop experience into one marked by increased efficiency and reduced downtime. Embracing this technology not only enhances operational workflows but also positions workshops to meet the demands of a rapidly changing industrial environment.

Benefits of Using Gas Air Compressors for Enhanced Workshop Productivity

Gas air compressors have become essential tools in modern workshops, revolutionizing the way tradespeople and hobbyists approach their tasks. According to a report by the Compressed Air and Gas Institute, gas air compressors can deliver power and versatility, significantly enhancing productivity and efficiency. They are not limited by electrical outlets, allowing for greater mobility and ease of use in various environments, whether on construction sites or in outdoor workshops. This flexibility enables users to tackle larger projects without the constraints of electrical availability.

The benefits of using gas air compressors extend beyond mobility. A report by the International Association of Compressed Air Contractors indicates that gas-powered compressors often provide higher pressure outputs compared to their electric counterparts. This capability is crucial for heavy-duty applications, such as powering pneumatic tools, spray painting, and sandblasting. Improved performance can dramatically reduce job completion times, allowing for a more efficient workflow.

Additionally, gas compressors typically require less maintenance over time, translating into less downtime and lower operational costs for workshop owners. Thus, investing in a gas air compressor can yield substantial returns through enhanced productivity and reduced long-term expenses.

Key Advantages of Gas vs. Electric Compressors in Industrial Settings

In the realm of industrial settings, the choice between gas and electric compressors can significantly influence operational efficiency. Gas air compressors are renowned for their mobility and power. They are particularly advantageous in remote job sites where electricity may be unavailable. Equipped with robust engines, these compressors can deliver high-pressure air that is essential for heavy-duty applications, such as powering pneumatic tools and equipment. This independence from electrical outlets allows technicians to perform tasks in various environments without being tethered to a power source.

Conversely, electric compressors offer their own set of benefits, primarily in terms of energy efficiency and lower noise levels. They are ideal for indoor workshops where sound reduction is crucial. However, they may be limited by the need for a steady electrical supply and can struggle with high-demand tasks without significant investment in power upgrades. Ultimately, the decision between gas and electric compressors will depend on the specific requirements of the workshop, including power needs, operational environments, and the type of tasks being performed. This nuanced understanding of each type can lead to optimized performance and enhanced productivity in industrial settings.

Gas vs. Electric Air Compressors: Key Efficiency Metrics

Impact of Compressed Air Systems on Workshop Efficiency and Output

Compressed air systems have become essential tools in modern workshops, significantly enhancing efficiency and productivity. According to a report by the Industrial Technology Institute, air compressors can increase operational efficiency by up to 30% when integrated into workshop processes. This improvement stems from air compressors' ability to power various tools and equipment, enabling seamless transitions between tasks without downtime.

Moreover, leveraging a gas air compressor helps reduce the overall energy consumption of workshop systems. The U.S. Department of Energy states that compressed air systems can account for nearly 30% of a facility's electricity costs, making their efficient use critical. By optimizing the settings and load requirements of these systems, workshops can achieve noteworthy energy savings while maintaining high output levels. This translates to a more sustainable operation, allowing businesses to invest resources elsewhere, thus driving innovation and growth. Integrating a gas air compressor not only streamlines workflows but also positions workshops to adapt to increasing demands effectively.

Industry Data: Cost Savings and Performance Improvements from Gas Air Compressors

Gas air compressors are revolutionizing workshop dynamics by delivering substantial cost savings and impressive performance improvements. In various industries, the efficiency delivered by these compressors can significantly reduce operational expenses. By utilizing gas compressors, businesses often witness lower energy costs compared to electric alternatives, particularly in remote locations where electricity may be unreliable or expensive. This allows workshops to allocate resources more effectively, leading to enhanced profitability.

Additionally, gas air compressors contribute to better workflow management. With their ability to provide high-power output and continuous operation, these compressors enable workers to accomplish tasks more swiftly and with less downtime. Many industries have reported increased productivity levels, as equipment powered by gas compressors operates effectively under demanding conditions. The versatility and reliability of gas compressors not only streamline processes but also enhance the overall workshop experience, driving performance metrics upward and ensuring that operational goals are met efficiently.

Case Studies: Transformative Effects of Gas Air Compressors in Real Workshops

Gas air compressors are transforming workshops by significantly enhancing efficiency and productivity. Numerous case studies illustrate how various industries incorporate gas air compressors to streamline their operations. For instance, in automotive repair shops, the use of gas air compressors allows for quicker tire changes and paint jobs, thereby decreasing downtime and improving customer satisfaction. In construction sites, these compressors power pneumatic tools with consistent air supply, enabling workers to complete tasks more rapidly and effectively.

Gas air compressors are transforming workshops by significantly enhancing efficiency and productivity. Numerous case studies illustrate how various industries incorporate gas air compressors to streamline their operations. For instance, in automotive repair shops, the use of gas air compressors allows for quicker tire changes and paint jobs, thereby decreasing downtime and improving customer satisfaction. In construction sites, these compressors power pneumatic tools with consistent air supply, enabling workers to complete tasks more rapidly and effectively.

Tips for Maximizing Workshop Efficiency:

- Regular Maintenance: Ensure your gas air compressor is properly maintained to prevent unexpected downtimes and maintain optimal performance.

- Proper Sizing: Select a compressor that is the right size for your applications to avoid energy wastage and inefficiencies.

- Evaluate Usage: Monitor how much air your tools consume and adjust your compressor settings to meet those needs efficiently.

With advancements such as remote monitoring, similar to the digital twin technology seen in the oil and gas sector, workshop operators can track compressor performance in real-time. This capability can lead to proactive maintenance and further cost reductions, making gas air compressors an essential asset in modern workshops.

Related Posts

-

Real World Applications of Rotary Screw Air Compressors in Various Industries

-

Exploring Portable Air Compressor Innovations at the 2025 China Import and Export Fair

-

Understanding the Mechanisms Behind Electric Air Compressors: A Deep Dive into Their Functionality

-

7 Essential Features of the Best Portable Air Compressors for Every Home

-

Common Issues Faced When Choosing Air Dryers for Compressors

-

Desiccant Air Dryer Showdown: Which Option Delivers the Best Performance for Your Needs?