24 Hour Service

24 Hour Service- 800.825.3222

- Now Hiring

- Request A Quote

Blog

Understanding the Impact of Quality Compressor Parts on Industrial Efficiency and Maintenance Costs

In the industrial sector, the performance of machinery often hinges on the quality of its components, and this is particularly true for compressor systems. According to a recent report by the International Compressor Manufacturers Association, it has been shown that investing in high-quality compressor parts can improve operational efficiency by over 15% and significantly reduce overall maintenance costs. As industries strive for increased productivity and lower expenditure, understanding the implications of these components becomes crucial.

Expert in the field, Dr. Alice Johnson, a leading authority on industrial machinery, emphasizes the importance of compressor parts in her studies, stating, “The longevity and efficiency of a compressor are directly tied to the quality of its parts; choosing subpar components can lead to a cascade of operational failures and rising costs.” This insight highlights the pressing need for industries to prioritize quality in their procurement processes, ensuring that their compressor systems function optimally while minimizing downtime.

Furthermore, as global competition intensifies, the demand for reliable and efficient machinery has never been greater. Companies that neglect the significance of superior compressor parts may find themselves not only facing increased maintenance challenges but also losing their competitive edge. By understanding the impact of these critical components, businesses can make informed decisions that bolster their productivity and maintain their profitability in an ever-evolving landscape.

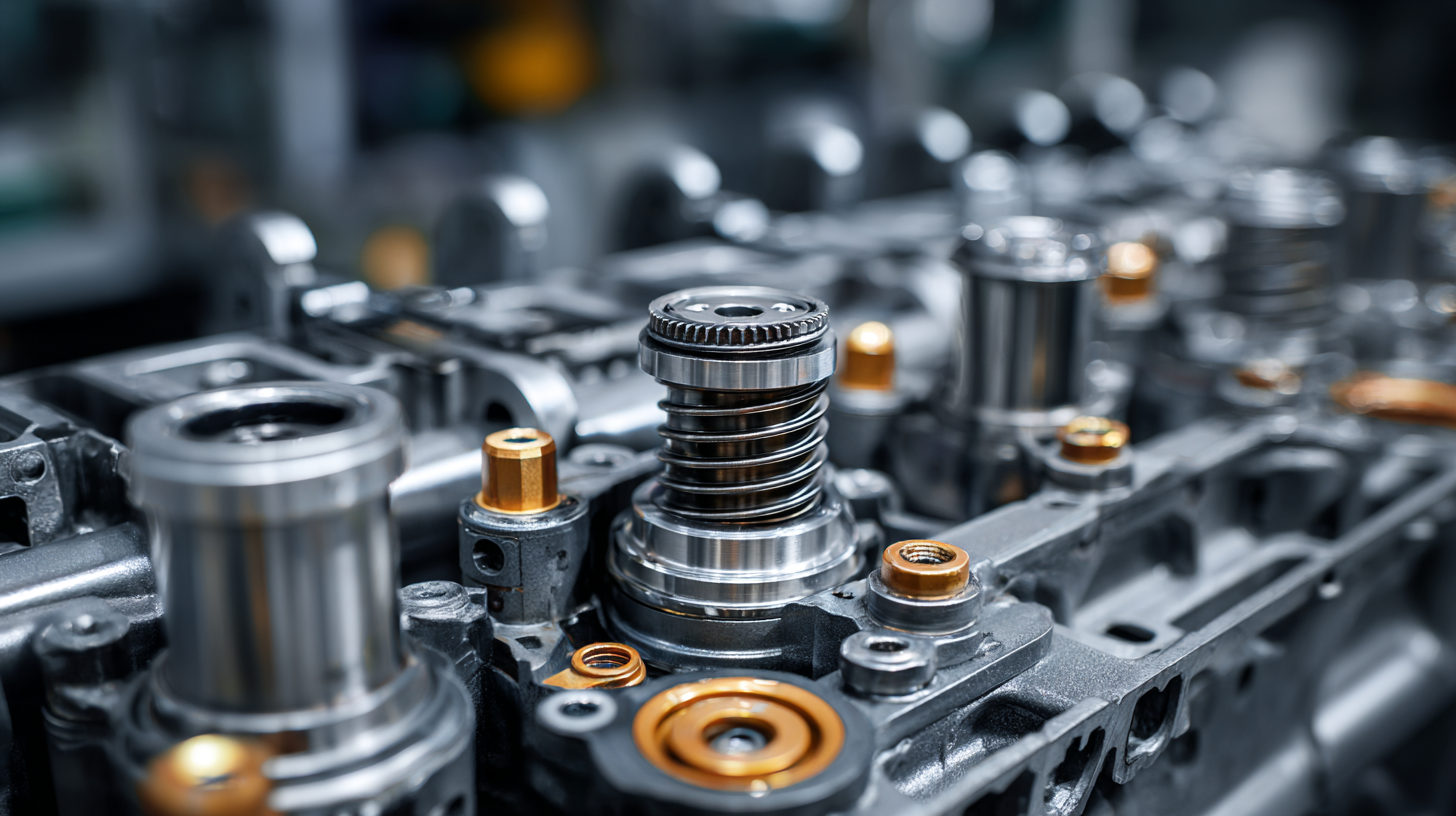

Choosing the Right Compressor Parts for Optimal Performance

Choosing the right compressor parts is crucial for optimal performance in various applications, especially within the automotive sector. The automotive air conditioning compressor market is expected to reach $101,364 million in 2024, rising to $121,720 million by 2032, reflecting a robust growth rate of 2.31%. This growth underscores the increasing demand for efficient and reliable compressor systems, signifying that the quality of compressor components can directly influence performance and maintenance costs.

When selecting compressor parts, considerations extend beyond just compatibility. High-quality components can enhance the efficiency of the entire system, leading to reduced energy consumption and lower operational costs. As most Chinese consumers depend heavily on their cars, with nearly 70% of commuters opting for personal vehicles, ensuring the robustness and longevity of compressor parts is essential. Frequent repairs due to substandard components can escalate maintenance expenses and detract from overall vehicle performance, making informed purchasing crucial for both manufacturers and consumers in the automotive market.

Evaluating the Quality Standards of Compressor Components

The quality of compressor components is pivotal in determining the overall performance and reliability of industrial systems. According to a report by the American Society of Mechanical Engineers (ASME), nearly 30% of compressor failures can be traced back to subpar parts, which emphasizes the need for stringent quality standards. High-quality materials and precision manufacturing not only enhance the efficiency of compressors but also extend their lifespan, thereby minimizing downtime and replacement costs.

Evaluating the quality standards of compressor components involves rigorous testing and adherence to industry benchmarks. The International Organization for Standardization (ISO) sets forth guidelines that many manufacturers follow to ensure their products meet performance and safety requirements. For instance, ISO 9001 certification is a key indicator of a manufacturer’s commitment to quality management principles. Additionally, a study by Frost & Sullivan highlights that companies adopting high-quality compressor parts have reported up to a 20% reduction in maintenance costs and a 15% increase in operational efficiency. Hence, investing in quality parts is not merely a cost consideration but a strategic decision towards enhancing productivity in industrial operations.

Impact of Quality Compressor Parts on Efficiency and Maintenance Costs

The following chart illustrates the correlation between the quality of compressor components and their impact on industrial efficiency and maintenance costs.

Impact of Quality Parts on Energy Efficiency in Industrial Systems

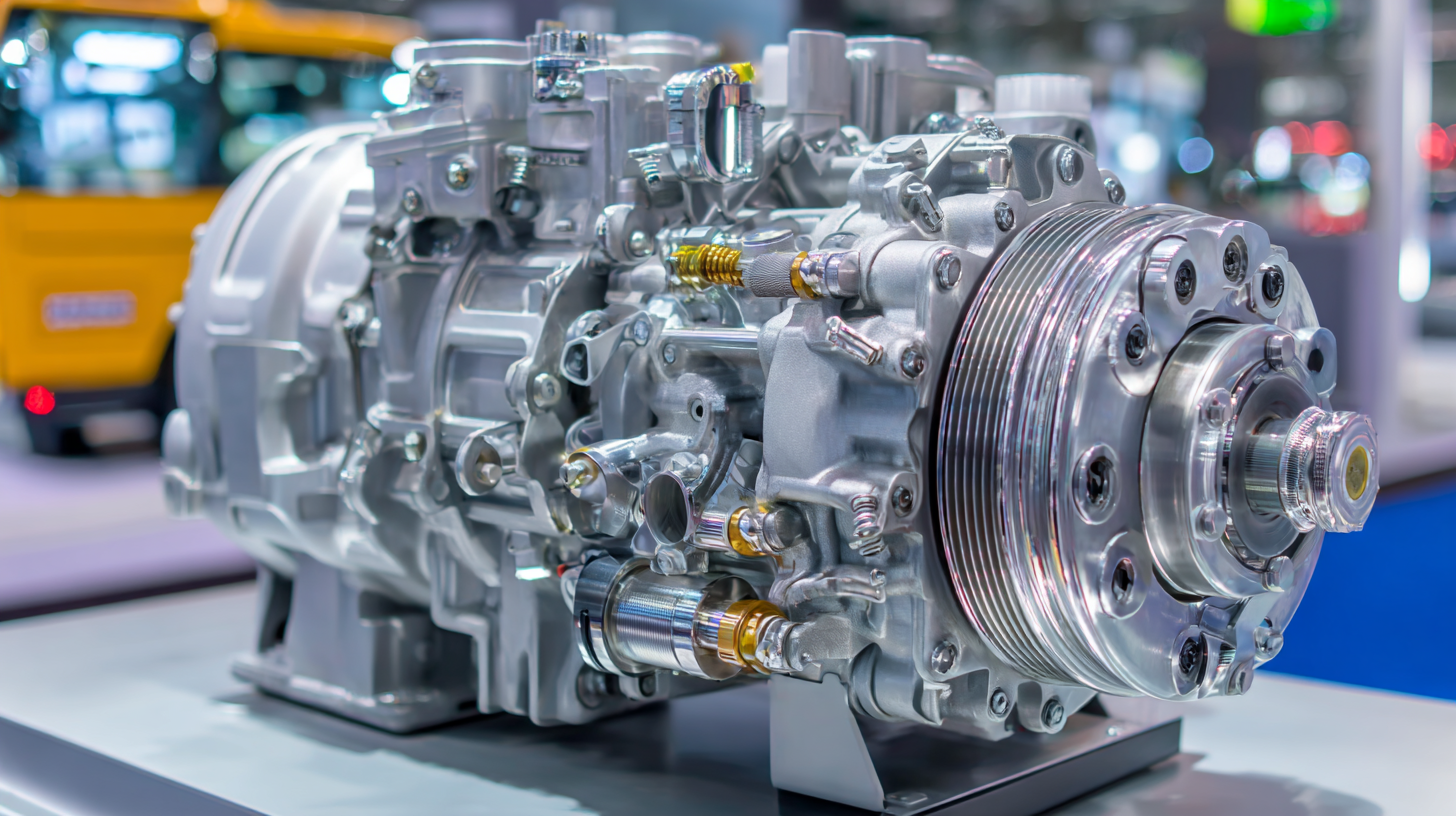

In industrial systems, the quality of compressor parts plays a crucial role in enhancing energy efficiency. High-quality components are designed to operate with precision, reducing energy consumption while maximizing performance. When compressors are equipped with durable and efficient parts, they can maintain optimal operating conditions, leading to lower energy usage and reduced operational costs. This focus on energy efficiency aligns with broader trends in industry, where the push for sustainable practices is essential for competitive advantage and compliance with environmental regulations.

Moreover, investing in quality compressor parts can significantly lower maintenance costs over time. Durable components require fewer replacements and less frequent repairs, which not only reduces direct expenses but also minimizes downtime. This is particularly important in manufacturing contexts, where interruptions can lead to substantial losses. As companies strive for enhanced energy efficiency and sustainable practices, the integration of high-quality parts becomes a key strategy in achieving long-term operational and financial benefits.

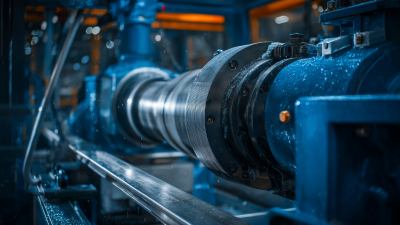

Strategies to Minimize Maintenance Costs with Quality Parts

Maintaining industrial machinery can be a daunting task, especially when it comes to compressor systems. One of the most effective strategies for minimizing maintenance costs is investing in quality compressor parts. High-quality components not only enhance the efficiency of the system but also reduce the frequency of breakdowns, leading to lower long-term operational costs.

Tip: Regularly assess the condition of your compressor parts. By keeping an eye on wear and tear, you can replace components preemptively, thus avoiding costly repairs caused by catastrophic failures.

Another crucial strategy involves implementing a routine maintenance schedule that includes the use of quality parts. This proactive approach ensures that your compressors run smoothly and remain in peak condition. Regular maintenance helps in identifying potential issues before they escalate, further reducing expenses associated with downtime and emergency repairs.

Tip: Educate your team on the importance of proper lubrication and cleaning of compressor parts. Simple maintenance practices can significantly extend the lifespan of your equipment and decrease the likelihood of unexpected failures.

Maintaining and Replacing Compressor Components for Longevity

Maintaining and replacing compressor components is crucial for ensuring the longevity and efficiency of industrial operations. Reports indicate that approximately 70% of compressor failures are related to wear and tear on critical components such as bearings and gaskets. Regular maintenance practices, including inspections and timely replacements, can significantly reduce downtime and extend the lifespan of these machinery parts. According to a study by the American Society of Mechanical Engineers (ASME), facilities that adhere to a rigorous maintenance schedule see a 20% increase in equipment longevity compared to those that neglect such protocols.

Furthermore, investing in high-quality replacement parts is essential for optimizing performance and minimizing maintenance costs. The International Compressor Manufacturing Association (ICMA) notes that using substandard components can lead to 30% more frequent failures, resulting in increased operational costs and unplanned outages. By prioritizing quality in component sourcing and ensuring proper maintenance routines, companies can not only enhance the efficiency of their compressors but also achieve substantial savings over time, reinforcing the importance of a strategic approach to maintenance and replacement in industrial settings.

Understanding the Impact of Quality Compressor Parts on Industrial Efficiency and Maintenance Costs

| Component Type | Average Lifespan (Years) | Impact on Efficiency (%) | Maintenance Cost ($) | Replacement Frequency (Years) |

|---|---|---|---|---|

| Compressor Pump | 7 | 15 | 500 | 5 |

| Air Filter | 3 | 10 | 200 | 1 |

| Oil Separator | 5 | 12 | 300 | 4 |

| Motor | 10 | 20 | 800 | 8 |

| Valves | 6 | 8 | 150 | 2 |

Related Posts

-

Desiccant Air Dryer Showdown: Which Option Delivers the Best Performance for Your Needs?

-

Understanding the Mechanisms Behind Electric Air Compressors: A Deep Dive into Their Functionality

-

How to Select the Right Air Dryer for Your Compressor Needs

-

Navigating the 2025 Landscape of Best Rotary Screw Compressors and Their Impact on Global Procurement

-

Revolutionizing Industrial Cleaning: How Air Knife Blowers Increase Efficiency by 30% Over Traditional Methods

-

Understanding the Challenges Faced by Global Buyers in Sourcing Desiccant Air Dryers