24 Hour Service

24 Hour Service- 800.825.3222

- Now Hiring

- Request A Quote

Blog

Top 10 Essential Air Compressor Parts You Need for Optimal Performance

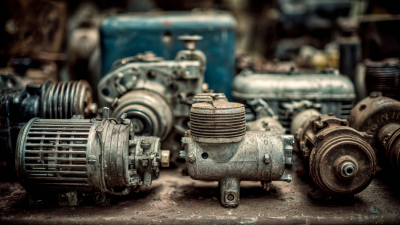

Air compressors are vital tools in a variety of industries, providing the necessary power for a wide range of applications. To achieve optimal performance from your air compressor, understanding the essential air compressor parts is crucial. Each component plays a specific role in ensuring that the machine operates efficiently and effectively, delivering the compressed air required for your tasks. From the motor to the pressure switch, each part contributes to the overall functionality of the compressor.

In this article, we will explore the top ten essential air compressor parts that are necessary for maintaining peak performance. We’ll delve into their functions, importance, and how they interact to enhance the efficiency and reliability of your air compressor. Whether you're a seasoned professional or a DIY enthusiast, having a solid grasp of these components will empower you to make informed decisions about maintenance and upgrades, ultimately leading to improved productivity and extended lifespan of your air compressor.

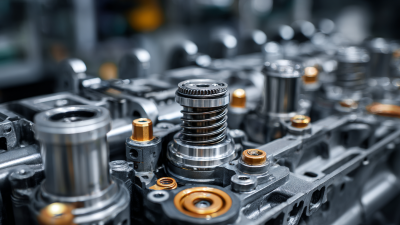

Essential Components of Air Compressors for Peak Efficiency

Air compressors are vital tools in various industries, and understanding their essential components is key to ensuring peak efficiency. One of the core parts is the compressor pump, which converts electrical energy into mechanical energy. This pump is responsible for compressing the air, making it a critical element for optimal performance. A well-functioning pump not only enhances the unit's efficiency but also extends its lifespan by reducing wear and tear.

Another crucial component is the air receiver tank, which stores compressed air for future use. This tank helps to maintain consistent pressure levels and minimizes the risk of fluctuations that could affect downstream tools and equipment. Additionally, the inclusion of appropriate filters plays a significant role in maintaining air quality. High-quality filters prevent contaminants from entering the system, ensuring a reliable and clean air supply.

Together, these parts work harmoniously to promote the overall efficiency of the air compressor, making it essential for users to pay close attention to their maintenance and functionality.

Understanding the Role of Air Intake Filters in Compressor Performance

The air intake filter plays a crucial role in the overall performance of an air compressor. It serves as the first line of defense against contaminants, effectively filtering out dirt, dust, and moisture from the air before it enters the compressor's internal components. A clean and efficient air intake filter ensures a consistent and high-quality airflow, which is essential for maintaining optimal pressure levels and reducing the risk of mechanical failures. When the filter becomes clogged or dirty, it not only impairs airflow but also forces the compressor to work harder, leading to increased energy consumption and premature wear.

Regular maintenance of the air intake filter is vital for ensuring the longevity and efficiency of the compressor. Depending on the operating environment, filters may require frequent inspection and replacement. A well-maintained air intake filter not only contributes to better compressor performance but also enhances the quality of the compressed air output, making it suitable for various applications. Understanding the importance of this component allows operators to make informed decisions regarding maintenance schedules, thereby maximizing the operational lifespan of their equipment while minimizing downtime and repair costs.

Top 10 Essential Air Compressor Parts for Optimal Performance

This bar chart illustrates the importance of various essential air compressor parts in ensuring optimal performance, specifically focusing on the role of air intake filters.

The Importance of Pressure Regulators in Air Compressor Systems

Pressure regulators are vital components in air compressor systems, serving a crucial role in maintaining consistent and safe operational levels. They ensure that the pressure delivered to the tools and equipment remains stable, regardless of fluctuations in the compressor's output. This stability is essential because many pneumatic tools and machines are designed to operate within specific pressure ranges. By accurately regulating the airflow, pressure regulators prevent damage to tools and enhance their longevity.

The significance of pressure regulators goes beyond just protecting equipment. They also contribute to the efficiency of the entire air compressor system. When the pressure is kept within appropriate limits, energy consumption is optimized, leading to lower operational costs. Additionally, regulators help to prevent pressure spikes which can cause safety risks, including potential injuries. Properly functioning pressure regulators thus enhance the overall reliability and performance of air compressor systems, making them indispensable for both industrial and DIY applications.

Exploring the Function of Air Receivers in Compressor Operations

Air receivers play a crucial role in the operation of air compressors by acting as a buffer between the compressor and the pneumatic system. Their primary function is to store compressed air, which allows for a consistent supply to downstream tools and equipment. By moderating the air pressure and smoothing out fluctuations, air receivers contribute to the efficiency of the entire compressed air system. This stabilization prevents potential damage to tools and machinery that can occur due to inconsistent air flow, ensuring optimal performance during operation.

Moreover, air receivers facilitate moisture separation and help improve air quality. As air is compressed, it naturally contains a certain amount of moisture, which can lead to corrosion and reduced efficiency within the system. A well-designed air receiver allows for the condensation of moisture, which can be drained off periodically, maintaining the integrity of the compressed air and protecting downstream components. This aspect is vital for applications where clean and dry air is essential for optimal performance, thereby extending the lifespan of the equipment and boosting productivity in various industrial settings.

Maintenance Tips for Key Air Compressor Parts to Ensure Longevity

Maintaining the essential parts of your air compressor is crucial for ensuring its optimal performance and longevity. Regular maintenance not only enhances efficiency but also prevents costly repairs down the line.

One of the most important components to monitor is the air filter. A clogged filter can restrict airflow, increasing energy consumption and wear on the compressor. Tips: Check the air filter monthly and clean or replace it as needed to maintain proper airflow. Ensure that you are using the correct filtration type appropriate for your environment, as this can significantly impact performance.

Another key part to focus on is the oil separator. A well-functioning oil separator is necessary for protecting the compressor from contamination and reducing oil carryover. Tips: Regularly inspect the oil separator for signs of wear or degradation, and replace it according to your maintenance schedule. Keeping an eye on the oil level and quality will also help ensure optimal lubrication and function.

Lastly, don't overlook the importance of regular inspections for the pressure switch and safety valves. These components are vital for monitoring and controlling the compressor's operation. Tips: Test the pressure switch settings regularly and ensure the safety valves are functioning correctly to prevent any pressure-related accidents. Keeping these components in check will not only enhance performance but also extend the overall lifespan of your air compressor.

Top 10 Essential Air Compressor Parts You Need for Optimal Performance

| Part Name | Function | Maintenance Tips | Expected Lifespan |

|---|---|---|---|

| Air Filter | Removes contaminants from the air intake | Check regularly, replace when dirty or every 3-6 months | 1-2 years |

| Oil Filter | Filters impurities from the oil | Change every 3 months or according to usage | 1 year |

| Compressor Pump | Compresses air for storage in the tank | Lubricate regularly, inspect for wear | 5-10 years |

| Pressure Switch | Regulates pressure levels in the tank | Check connections and calibration periodically | 3-5 years |

| Tank | Stores compressed air | Inspect for rust and corrosion, drain regularly | 10-15 years |

| Regulator | Controls the output pressure of air | Test pressure settings and connections routinely | 3-5 years |

| Cooling System | Cools the compressed air during operation | Ensure air vents are clear and clean | 5-10 years |

| Hoses | Transports compressed air to tools | Inspect for leaks and wear; replace if damaged | 2-5 years |

| Unloader Valve | Relieves pressure when the compressor is off | Test functionality periodically and keep clean | 5-7 years |

Related Posts

-

Ultimate Guide to Understanding Air Compressor Parts for Optimal Performance

-

Understanding the Impact of Quality Compressor Parts on Industrial Efficiency and Maintenance Costs

-

Top 10 Best Refrigerated Air Dryers for Your Industrial Needs

-

What is an Air Compressor Water Separator and How Does It Work

-

Common Issues Faced When Choosing Air Dryers for Compressors

-

Understanding the Mechanisms Behind Electric Air Compressors: A Deep Dive into Their Functionality