24 Hour Service

24 Hour Service- 800.825.3222

- Now Hiring

- Request A Quote

Blog

Why Choose a Desiccant Air Dryer for Optimal Moisture Control in Your System

In industrial environments, maintaining optimal moisture control is crucial for the efficiency and longevity of equipment and processes. According to the Compressed Air and Gas Institute (CAGI), moisture can lead to significant performance issues, resulting in early wear and corrosion, which can cost businesses an average of 15% in production downtime and maintenance expenses. This highlights the importance of investing in effective moisture management solutions, such as a desiccant air dryer.

Desiccant air dryers are renowned for their ability to provide superior moisture control compared to traditional refrigeration-based systems. By utilizing hygroscopic materials to absorb moisture from compressed air, these systems can achieve dew points as low as -40°F (-40°C), ensuring that air quality meets the stringent requirements of various industries. A recent report by the International Society for Air Quality and Climate found that implementing desiccant air dryers not only enhances system reliability but also improves overall energy efficiency, demonstrating an average energy savings of 20-30% when compared to other drying methods.

With the growing demand for high-quality air in manufacturing, pharmaceuticals, and food processing, the role of desiccant air dryers becomes increasingly vital. Investing in a desiccant air dryer can not only mitigate the risks associated with moisture but also optimize productivity and safeguard expensive equipment, underscoring why they are a preferred choice for moisture control in modern industrial systems.

Benefits of Desiccant Air Dryers for Moisture Control

Desiccant air dryers play a crucial role in maintaining optimal moisture control in various systems. These dryers utilize desiccant materials that actively absorb moisture from the compressed air, ensuring that the air supply remains dry and free from water vapor. This process is essential in applications where moisture can cause significant damage, such as in food processing, pharmaceuticals, and manufacturing. By effectively removing moisture, desiccant air dryers help enhance product quality and extend the lifespan of equipment.

One of the primary benefits of using desiccant air dryers is their ability to achieve low dew points, even in environments with high humidity. This capability is particularly important for industries that require exceptionally dry air to prevent corrosion and contamination. Additionally, desiccant air dryers are versatile and can be configured to meet specific operational needs, making them suitable for both small-scale applications and large industrial processes. Their robust performance and reliability make them an ideal choice for businesses aiming to improve efficiency while safeguarding their equipment and processes from moisture-related issues.

Moisture Control Efficiency of Desiccant Air Dryers

This chart illustrates the efficiency of desiccant air dryers in reducing moisture levels in compressed air systems compared to other drying methods such as refrigerated and membrane dryers. The data reflects the average moisture content (in ppm) after each dryer type, demonstrating the superior moisture control offered by desiccant air dryers.

How Desiccant Technology Works in Air Drying Systems

Desiccant technology operates on the principle of adsorption, where moisture in the air is captured by a desiccant material, typically silica gel or activated alumina. These materials are known for their high surface area and porous structure, which allows them to attract and hold water vapor from the surrounding air effectively. In an air drying system, air is drawn through a bed of desiccant, causing the moisture to adhere to the surface of the desiccant particles. This process significantly reduces the humidity level in the air stream, making it ideal for applications that require dry air.

Once the desiccant becomes saturated with moisture, it must be regenerated to maintain efficiency. This regeneration process typically involves heating the desiccant to release the captured moisture, often using a portion of the dry air produced by the system itself or an external heat source. The ability to quickly cycle between adsorbing moisture when in use and releasing it during regeneration ensures that desiccant air dryers can provide continuous moisture control. This makes them particularly advantageous for systems where even slight humidity levels can cause operational issues or damage to sensitive equipment.

Applications and Industries Utilizing Desiccant Air Dryers

Desiccant air dryers are crucial in various applications across multiple industries that require stringent moisture control. In the manufacturing sector, they are widely used to protect sensitive equipment and materials from moisture-related damage. For example, in the food processing industry, maintaining low humidity levels is essential to prevent spoilage and ensure product quality. Similarly, in pharmaceuticals, desiccant air dryers play a vital role in preserving the integrity of active ingredients and ensuring compliance with stringent regulations.

In the electronics industry, desiccant air dryers help prevent corrosion and damage to intricate components by maintaining optimal humidity levels during production and storage. Additionally, industries such as automotive and textiles utilize these dryers to safeguard raw materials and final products from moisture that could compromise quality and performance. Furthermore, the oil and gas sector benefits from desiccant air dryers by ensuring the reliability of instruments and equipment that operate under extreme conditions. Overall, the versatility of desiccant air dryers makes them indispensable in maintaining quality and enhancing operational efficiency across diverse applications.

Why Choose a Desiccant Air Dryer for Optimal Moisture Control in Your System - Applications and Industries Utilizing Desiccant Air Dryers

| Application/Industry | Moisture Control Requirements | Benefits of Desiccant Dryers |

|---|---|---|

| Pharmaceuticals | Ultra-low humidity levels for sensitive products | Prevents contamination and ensures product stability |

| Food Processing | Maintaining product quality by preventing spoilage | Enhances shelf life and preserves flavor |

| Electronics | Control humidity in manufacturing processes | Reduces risk of short circuits and improves quality |

| Automotive | Preventing moisture damage to components | Increases reliability and longevity of parts |

| Textiles | Maintaining moisture levels for fabric integrity | Improves fabric quality and reduces static |

Comparing Desiccant Air Dryers with Other Dehumidification Methods

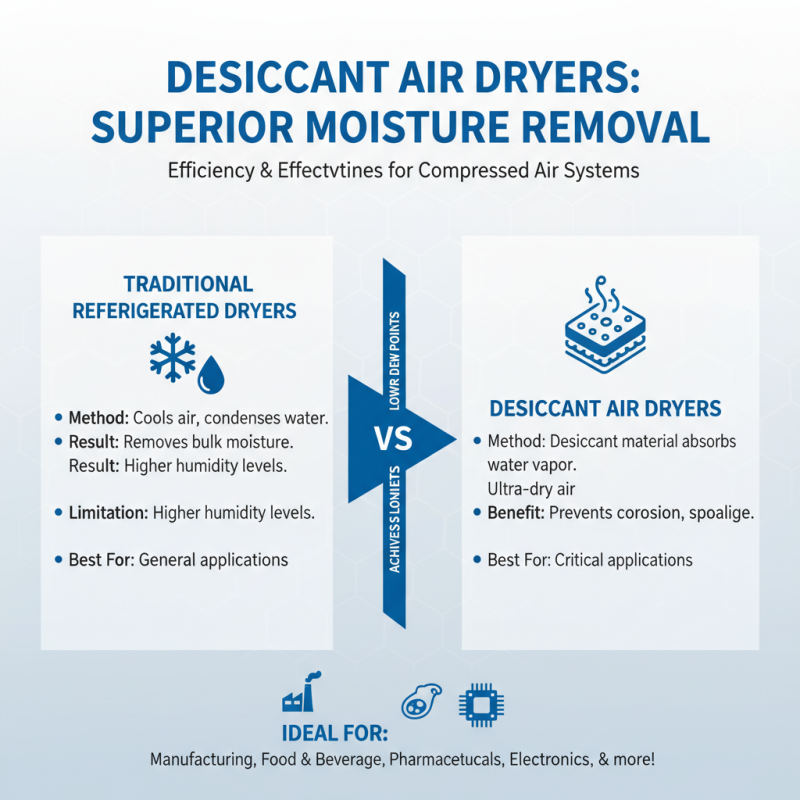

When it comes to managing moisture within compressed air systems, various dehumidification methods are available, but desiccant air dryers often stand out for their efficiency and effectiveness. Unlike traditional refrigerated air dryers, which rely on cooling and condensation to remove moisture, desiccant air dryers utilize a desiccant material to absorb water vapor from the air. This technology allows for achieving lower humidity levels, making it particularly beneficial in critical applications where moisture can lead to corrosion, product spoilage, or process inefficiency.

Additionally, compared to membrane or chemical drying methods, desiccant dryers offer the advantage of continuous operation without the need for constant monitoring of replacement materials. While membrane dryers work by selectively allowing water vapor to pass through while blocking other gases, they may not be suitable for very high dew point requirements. Chemical drying processes may rely on reactive agents that can degrade over time and necessitate periodic replacement. In contrast, the low maintenance and reliability of desiccant air dryers make them a preferred choice for industries requiring stringent moisture control, such as pharmaceuticals, food processing, and electronics manufacturing.

Maintenance Considerations for Effective Use of Desiccant Dryers

When it comes to optimal moisture control in industrial applications, desiccant air dryers are a popular choice due to their effectiveness in achieving low dew points. However, to maximize their performance and longevity, proper maintenance is a critical consideration. Regular inspection and servicing of desiccant dryers can significantly improve their efficiency; according to industry studies, neglecting maintenance can lead to a reduction in dryer performance by as much as 30%. Key maintenance tasks should include checking the regeneration cycle, inspecting for leaks, and replacing desiccant material periodically based on operational hours and environmental conditions.

Moreover, understanding the operational conditions and adapting maintenance strategies accordingly can further enhance the effectiveness of desiccant air dryers. Reports suggest that maintaining ambient temperatures within the optimal range can prevent desiccant saturation. For instance, in environments where humidity levels are high, performing more frequent regeneration cycles can keep moisture levels in check. Statistically, companies that follow a structured maintenance routine for their desiccant dryers experience up to a 20% increase in energy efficiency and a longer lifespan for the equipment, thus ensuring continuous and reliable performance in moisture-sensitive processes.

Related Posts

-

Real World Applications of Rotary Screw Air Compressors in Various Industries

-

Exploring Portable Air Compressor Innovations at the 2025 China Import and Export Fair

-

Understanding the Mechanisms Behind Electric Air Compressors: A Deep Dive into Their Functionality

-

Ultimate Guide to Choosing the Best Scroll Air Compressor for Your Business Needs

-

7 Essential Tips for Choosing the Best Oil Free Air Compressor

-

How to Select the Right Air Dryer for Your Compressor Needs