24 Hour Service

24 Hour Service- 800.825.3222

- Now Hiring

- Request A Quote

Blog

How to Choose the Right Refrigerated Air Dryer for Your Needs?

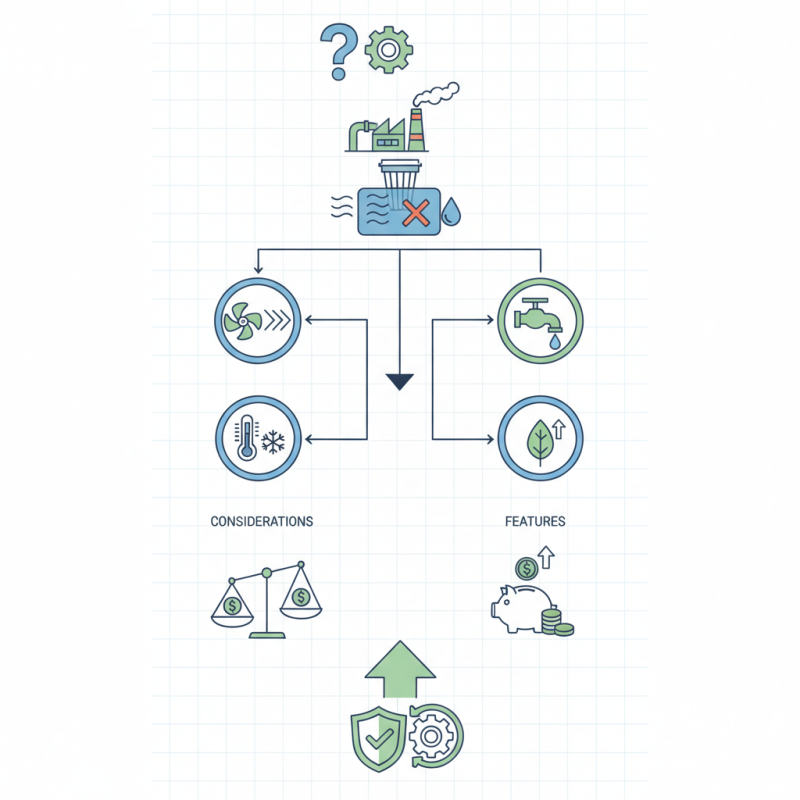

Choosing the right refrigerated air dryer is crucial for efficient operations. This equipment removes moisture from compressed air systems. By doing so, it prevents corrosion and maintains optimal performance.

When selecting a refrigerated air dryer, consider your specific needs. Factors like airflow requirements and operating conditions matter. A mismatch can lead to inefficiencies or even equipment damage. Sometimes, users focus too much on initial costs. They overlook long-term savings and productivity gains.

Additionally, the right features can enhance efficiency. For instance, automatic drains and energy-saving modes can lead to significant savings. It’s easy to underestimate these benefits. Taking time to evaluate options is essential. With the right choice, the refrigerated air dryer will improve your system's reliability.

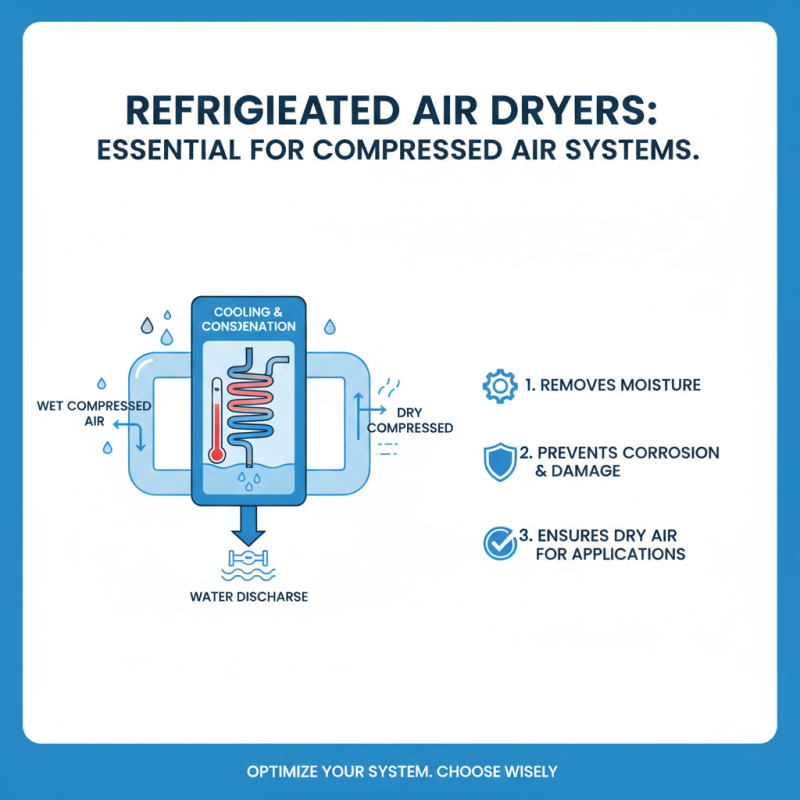

Understanding the Basics of Refrigerated Air Dryers and Their Functionality

Refrigerated air dryers play a crucial role in compressed air systems. They remove moisture, preventing corrosion and damage. This process involves cooling the compressed air, which condenses moisture. The water then drains out, ensuring dry air for your applications. Understanding these basics can guide you in selecting the right unit.

Different models offer varying capacities and efficiencies. Some can handle higher moisture loads better than others. A unit that's too small might not keep up with demand. This can lead to increased maintenance costs and equipment damage. It's essential to assess your specific needs carefully.

Monitoring your system's performance is also vital. Regular checks can reveal if the dryer is working optimally. If you notice excessive moisture downstream, it might indicate issues. Sometimes, adjustments are required for best results. These insights can lead to improved efficiency and extended equipment life. Choose wisely, as the right dryer makes a significant difference.

Evaluating Your Specific Compressed Air Needs and Applications

When selecting a refrigerated air dryer, it’s crucial to evaluate your specific compressed air needs. Consider the application of your compressed air system. For instance, industries like automotive may require lower dew points compared to pharmaceutical applications. According to the Compressed Air and Gas Institute, about 70% of compressed air systems are not optimized for energy efficiency.

Understanding your air quality requirements is also essential. If your processes are sensitive, you may need a dryer with a lower dew point. General air quality standards suggest maintaining a dew point around 35°F for most industrial applications. This can help in preventing moisture-related issues.

**Tips**:

- Assess your current air consumption.

- Analyze potential humidity issues in your facility.

- Consider future growth and expansion of your applications.

Remember, not all dryers are created equal. Sizing plays a significant role in performance. Oversized units can lead to energy inefficiency. Conversely, undersized models may struggle to keep up with demand. Strive to find a balance for reliable operation. Often, adjustments may be needed as production demands change over time. This reflection on your system's performance can guide you in making more informed choices.

How to Choose the Right Refrigerated Air Dryer for Your Needs?

| Application | Air Flow Rate (CFM) | Operating Pressure (PSI) | Dew Point (°F) | Power Supply (V/Ph/Hz) | Approximate Cost (USD) |

|---|---|---|---|---|---|

| Pneumatic Tools | 50 | 100 | 35 | 230/1/60 | $2,000 |

| Food & Beverage Processing | 100 | 80 | 38 | 460/3/60 | $3,500 |

| Pharmaceutical Manufacturing | 150 | 90 | 36 | 460/3/60 | $4,000 |

| Manufacturing and Assembly | 200 | 100 | 40 | 230/3/60 | $5,000 |

| Painting and Coating | 120 | 75 | 34 | 230/1/60 | $3,000 |

Key Technical Specifications to Consider in Air Dryer Selection

Choosing the right refrigerated air dryer involves understanding key technical specifications. The main factors include flow rate, pressure drop, and energy efficiency. According to a recent industry report, the average flow rate for industrial air dryers ranges from 50 to 500 SCFM. Knowing your system's specific needs is crucial for optimal performance.

When evaluating pressure drop, consider that a higher drop can lead to increased energy consumption. A study showed that every psi of pressure drop can equal a 1% decrease in system efficiency. Choosing the right dryer can mitigate this issue.

Tip: Always assess the air quality requirements of your application. If the air needs to be exceptionally dry, a high-efficiency model is necessary.

Energy efficiency is another critical specification. Many models now offer energy-saving modes. These can reduce operating costs by up to 30%. Opting for environmentally friendly options can save more than just money; it avoids unnecessary carbon footprints too.

Tip: Review your average air usage for peak times. This will help determine if a larger unit is warranted.

Recognizing these specifications enables you to make informed choices. Balancing performance with cost is essential. Consider both short-term and long-term impacts when selecting your refrigerated air dryer.

Comparing Energy Efficiency Ratings: Why They Matter for Your Costs

When selecting a refrigerated air dryer, energy efficiency is a critical factor. It directly impacts operational costs. According to the U.S. Department of Energy, compressed air systems account for about 10% of total industrial energy use. The effectiveness of your air dryer can greatly influence these figures.

Energy efficiency ratings are vital. They indicate how well a dryer converts electrical energy into compressed air. High-efficiency models can reduce energy consumption by 15% or more. This savings is significant over time. Regularly analyzing energy bills may reveal hidden costs. Monitoring these metrics can help identify potential savings.

Tips for selection: Compare the energy factor (EF) of various models. Look for those with a low EF rating—they’re more efficient. Check for certifications that ensure compliance with energy standards. Additionally, consider the upfront costs versus long-term savings. Sometimes, investing more initially can lead to better efficiency down the road. Collect data and evaluate your specific needs. It’s essential to balance efficiency with actual workload requirements.

Energy Efficiency Ratings of Refrigerated Air Dryers

This chart compares the energy efficiency ratings of different types of refrigerated air dryers. Higher ratings lead to lower energy costs over time, which is crucial for operational efficiency. Choose wisely!

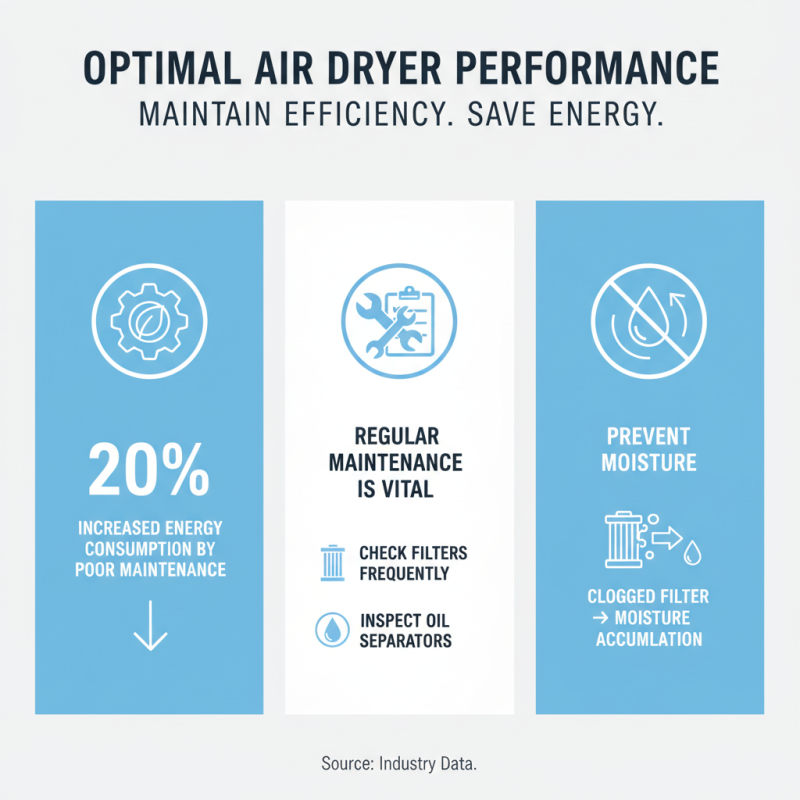

Maintenance Requirements and Lifecycle Considerations for Air Dryers

Maintaining an efficient air dryer is crucial for optimal performance. Data shows that poorly maintained air dryers can increase energy consumption by 20%. Regular maintenance is vital. Check the filters and oil separators frequently. A clogged filter can lead to moisture accumulation in your compressed air system.

Lifecycle considerations are equally important. Most air dryers last around 10 years, but factors can shorten their lifespan. These include excessive humidity and improper installation. A recent industry report indicates that nearly 30% of air dryers fail prematurely due to a lack of preventive maintenance. Monitor your system closely. Unexpected breakdowns can lead to costly repairs and downtime.

Be aware of the total cost of ownership. Cheap air dryers might save you money upfront but can result in higher long-term expenses. Energy efficiency and maintenance needs should weigh heavily in your decision. Consider the long-term implications of your choice. Many companies overlook these factors, leading to regret years later.

Related Posts

-

Top 10 Best Refrigerated Air Dryers for Your Industrial Needs

-

Understanding the Challenges Faced by Global Buyers in Sourcing Desiccant Air Dryers

-

What is a Small Air Compressor and How Can It Benefit Your Business

-

Top 10 Essential Air Compressor Parts You Need for Optimal Performance

-

Maximize Efficiency: How a Gas Air Compressor Transforms Your Workshop Experience

-

How to Choose the Right Air Dryer for Your Compressor Needs