24 Hour Service

24 Hour Service- 800.825.3222

- Now Hiring

- Request A Quote

Blog

How to Choose the Right Air Compressor Pump for Your Specific Needs

Choosing the right air compressor pump is essential for optimizing efficiency and performance tailored to your specific needs. With an array of options available in the market, from lightweight portable models to powerful industrial-grade units, understanding the distinct features and operational requirements of each air compressor pump can significantly impact your project outcomes.

This guide aims to simplify your decision-making process by highlighting key factors such as pump type, power requirements, and maintenance considerations. By evaluating your individual applications, whether for DIY tasks, automotive repair, or heavy-duty industrial work, you can make an informed choice that not only meets your performance expectations but also enhances productivity and longevity.

Let's explore the critical aspects of selecting the perfect air compressor pump for your unique requirements.

Understanding Different Types of Air Compressor Pumps Available on the Market

When selecting the right air compressor pump, it's crucial to understand the different types available on the market. The air compressor market is projected to see substantial growth, with a report indicating an expected market size of USD 8,221.1 million by 2033, growing at a compound annual growth rate (CAGR) of 6.8%. This growth is largely driven by an increasing demand across various industries for efficient and versatile air solutions.

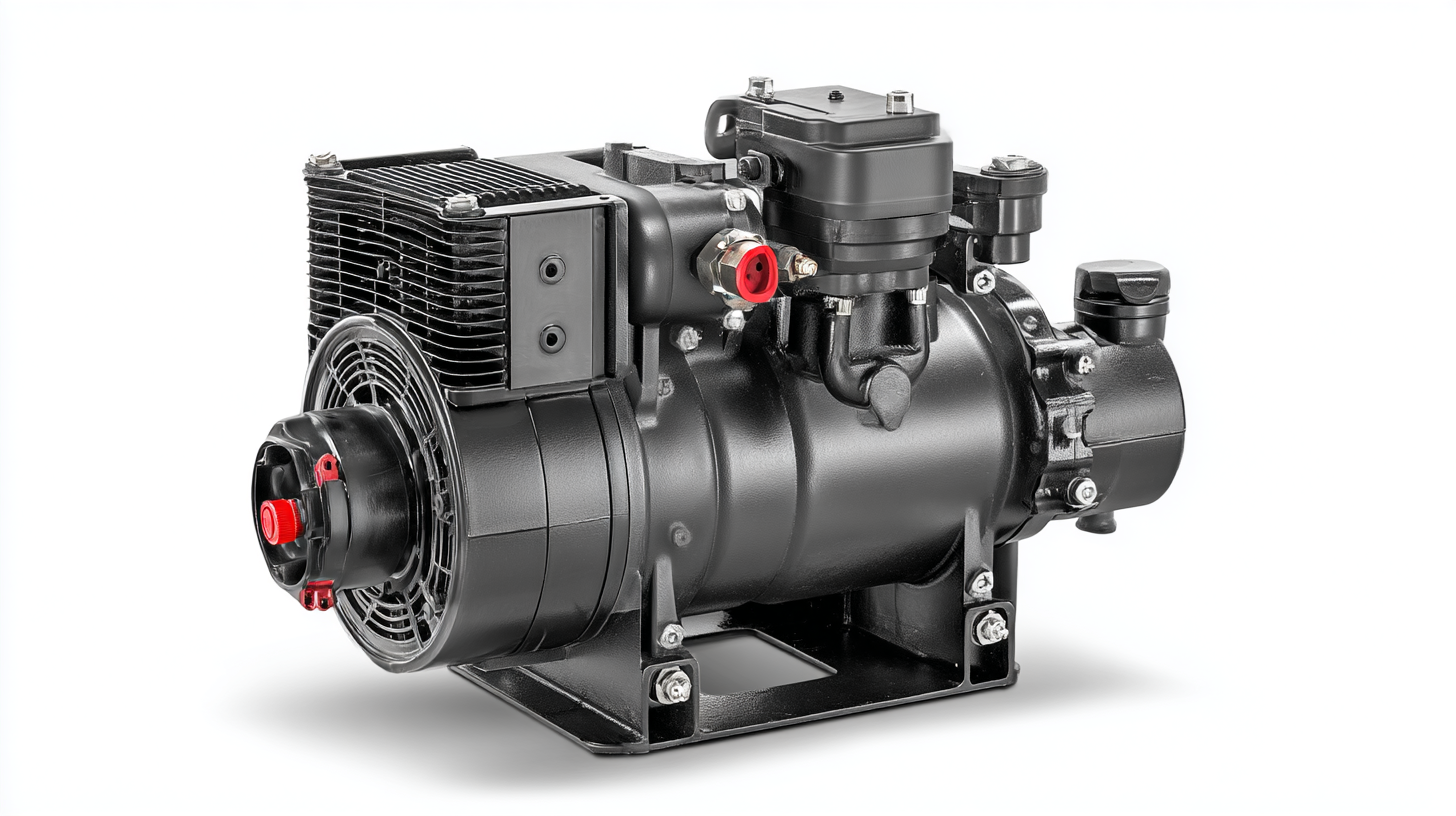

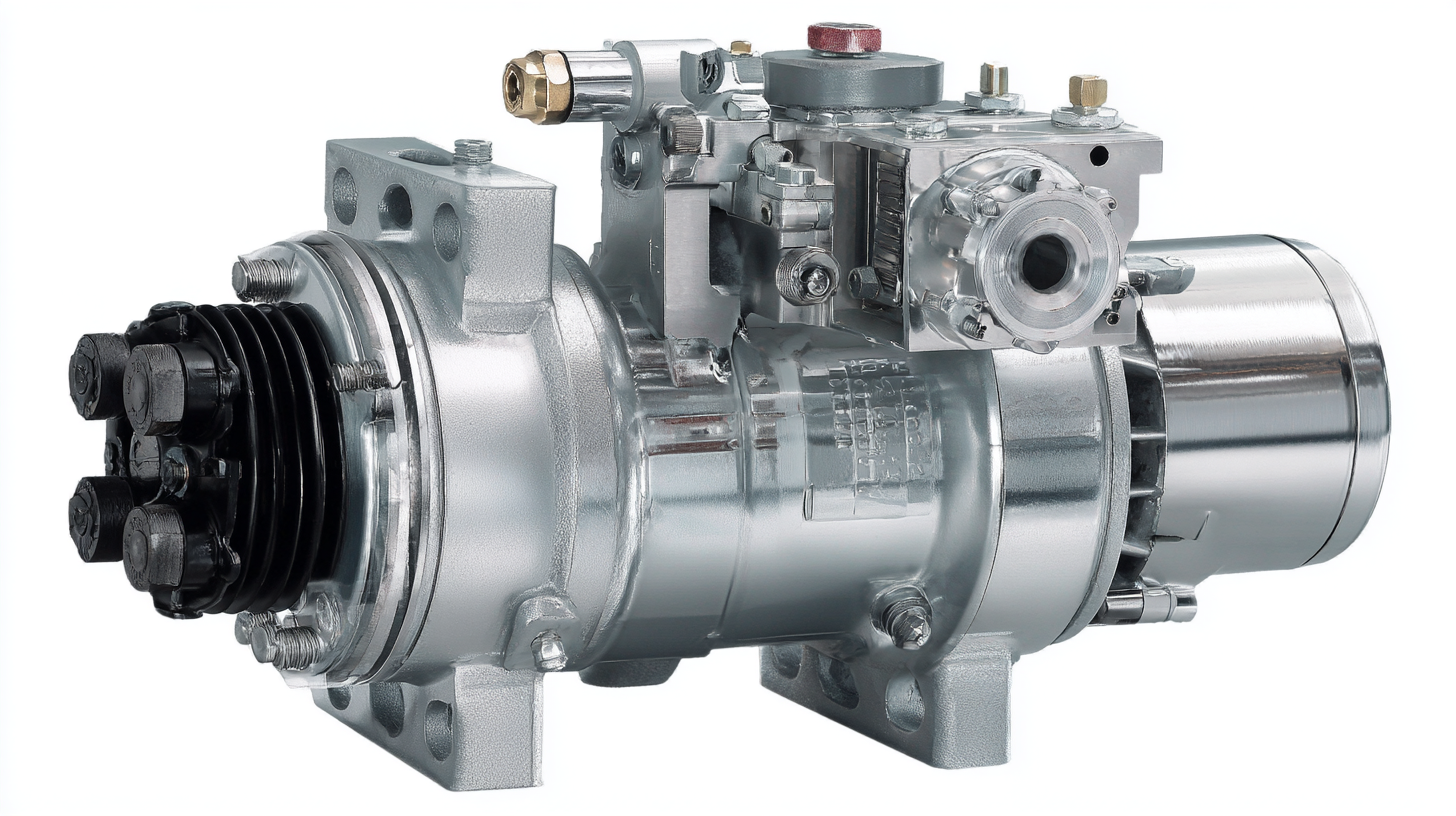

Air compressor pumps can be broadly categorized into several types: reciprocating, rotary, and centrifugal. Reciprocating pumps are known for their compact size and ability to produce high pressure, making them suitable for tasks like automotive repairs and small workshops. Rotary compressors, on the other hand, are favored in industrial settings for their reliability and efficiency in handling continuous operations. As highlighted in recent market analyses, the demand for portable air compressors is also on the rise, reflecting a shift towards more user-friendly and transportable equipment for both professional and home use. Understanding these distinctions can significantly affect your choice, ensuring you select a pump that aligns with your specific requirements.

Evaluating Performance Metrics: PSI, CFM, and Horsepower for Your Needs

When choosing the right air compressor pump for your specific needs, it’s crucial to evaluate key performance metrics like PSI (pounds per square inch), CFM (cubic feet per minute), and horsepower. These parameters significantly influence the efficiency and capability of the air compressor, directly impacting its performance in various applications. According to recent industry reports, a standard air compressor typically operates at a PSI range of 70 to 175, which determines the pressure output and the types of tools you can effectively use.

CFM is another critical metric, reflecting the volume of air the compressor can deliver. Reports indicate that applications ranging from nail guns to pneumatic tools might require different CFM ratings, generally between 2 to 10 CFM for smaller tasks and up to 30 CFM for industrial applications. Additionally, horsepower plays a vital role, with most small compressors running between 1 to 5 HP, while larger industrial models may exceed this significantly, ensuring sufficient power for heavy-duty tasks. Selecting the right combination of these metrics will allow you to optimize your air compressor pump's performance for your specific requirements.

Assessing the Size and Portability Requirements of Your Air Compressor Pump

When assessing the size and portability requirements of your air compressor pump, it's essential to consider the specific tasks you intend to perform. For home projects, a smaller, portable model may be ideal, particularly if you're working in tight spaces or need to transport the pump frequently. Compact air compressors typically provide sufficient power for tasks like inflating tires or running small pneumatic tools, ensuring that you can easily maneuver them around your workspace.

For those who anticipate more demanding applications, such as powering larger tools or completing extensive outdoor projects, the size of the air compressor becomes crucial. A larger tank capacity will allow for continuous operation without frequent refills. This is especially relevant for professionals or serious DIY enthusiasts who may require more robust performance. Keep in mind that while size often correlates with power, advancements in compressor technology have enabled the production of highly portable options without sacrificing efficiency, making it easier than ever to find the right balance for your needs.

Air Compressor Pump Size and Portability Requirements

This chart illustrates the portability ratings of different air compressor pump sizes, helping you make an informed decision based on both size and mobility needs.

Considering Power Sources: Electric vs. Gasoline Pumps for Specific Applications

When choosing the right air compressor pump for your specific needs, considering the power source is crucial. Electric pumps are often preferred for indoor use or applications where noise levels must be kept to a minimum. They are typically more efficient and environmentally friendly, requiring less maintenance than their gasoline counterparts. Electric pumps are ideal for tasks such as inflating tires, powering pneumatic tools, or running small spray guns, where a continuous, steady power supply is advantageous.

On the other hand, gasoline-powered pumps offer portability and are better suited for outdoor applications or job sites without access to electricity. These pumps tend to generate more power, making them suitable for heavy-duty tasks, such as construction work or large-scale painting projects. However, they require more maintenance and produce emissions, so they should be operated in well-ventilated areas. Understanding the specific requirements of your tasks will help you determine whether an electric or gasoline compressor pump is the right choice for your needs.

Budgeting: How to Find an Air Compressor Pump That Meets Your Financial Limits

When embarking on the journey to find the right air compressor pump within your financial constraints, the first step is to establish a clear budget. Understanding how much you are willing to invest will narrow down your options and prevent you from overspending. Consider not only the initial purchase price but also the long-term costs associated with maintenance, energy consumption, and potential repairs. This holistic view of budgeting ensures that the chosen air compressor pump aligns not only with your needs but also with your financial limits.

Once a budget is set, research different brands and models within that price range. Look for reliable reviews and user experiences to gauge the performance of each option. It might also be beneficial to compare features that are essential for your specific tasks. Some pumps may have lower upfront costs but higher lifetime expenses, while others could be pricier initially yet more efficient and durable in the long run. Balancing performance with cost will help you find an air compressor pump that meets both your requirements and your budget.

How to Choose the Right Air Compressor Pump for Your Specific Needs

| Air Compressor Pump Type | Max PSI | CFM Rating | Power Source | Estimated Price ($) |

|---|---|---|---|---|

| Piston Pump | 135 | 6.5 | Electric | 300 |

| Rotary Screw Pump | 150 | 10.0 | Diesel | 1200 |

| Diaphragm Pump | 80 | 3.5 | Electric | 250 |

| Scroll Pump | 100 | 4.5 | Electric | 700 |

| Vane Pump | 90 | 5.2 | Electric | 350 |

Related Posts

-

What is a Small Air Compressor and How Can It Benefit Your Business

-

How to Select the Right Air Dryer for Your Compressor Needs

-

Ultimate Guide to Understanding Air Compressor Parts for Optimal Performance

-

Ultimate Guide to Choosing the Best Scroll Air Compressor for Your Business Needs

-

Desiccant Air Dryer Showdown: Which Option Delivers the Best Performance for Your Needs?

-

Unique Examples of Air Dryer Solutions for Compressors