24 Hour Service

24 Hour Service- 800.825.3222

- Now Hiring

- Request A Quote

Blog

How to Choose the Right Rotary Screw Compressor for Your Needs?

Selecting the right rotary screw compressor is critical for industrial efficiency. In recent years, the global market for rotary screw compressors has been projected to reach $10 billion by 2026. This growth reflects their increasing use in various applications, from manufacturing to energy generation.

Many industries rely on rotary screw compressors for reliable compressed air. They offer continuous airflow, which is essential for many processes. With over 40% of businesses reporting higher energy savings from modern rotary screw compressors, it’s clear they are a sound investment. However, choosing the right model can be challenging. Factors such as capacity, efficiency, and noise levels must be considered.

Reflecting on the diverse models available, not all may suit every need. A mismatch can lead to wasted energy or insufficient airflow. It’s vital to assess your specific requirements carefully. Exploring data and expert recommendations can aid in making an informed decision. Ultimately, the right choice can significantly impact overall performance and cost efficiency in operations.

Understanding Rotary Screw Compressors and Their Applications

Rotary screw compressors are essential in various industries. They compress air or gas for different applications, like manufacturing and HVAC systems. Understanding their working principles is crucial. These machines use two rotors to compress air continuously. This design minimizes energy consumption and maximizes efficiency.

Applications of rotary screw compressors range widely. They are often found in production lines, where large volumes of compressed air are required. In food processing, they help maintain hygiene by powering equipment. However, choosing the right model can be challenging. Users must consider factors such as airflow requirements and pressure levels. What seems right may not always fit specific needs.

Sometimes, people underestimate the importance of maintenance. A lack of preventative measures can lead to unexpected downtime. Regular checks are necessary to ensure optimal performance. Additionally, size and noise levels are often overlooked. Compressors that are too loud can disrupt operations. Balancing these factors is key to making a smart decision. Many find the process of selection complex but rewarding.

Key Factors to Consider When Selecting a Rotary Screw Compressor

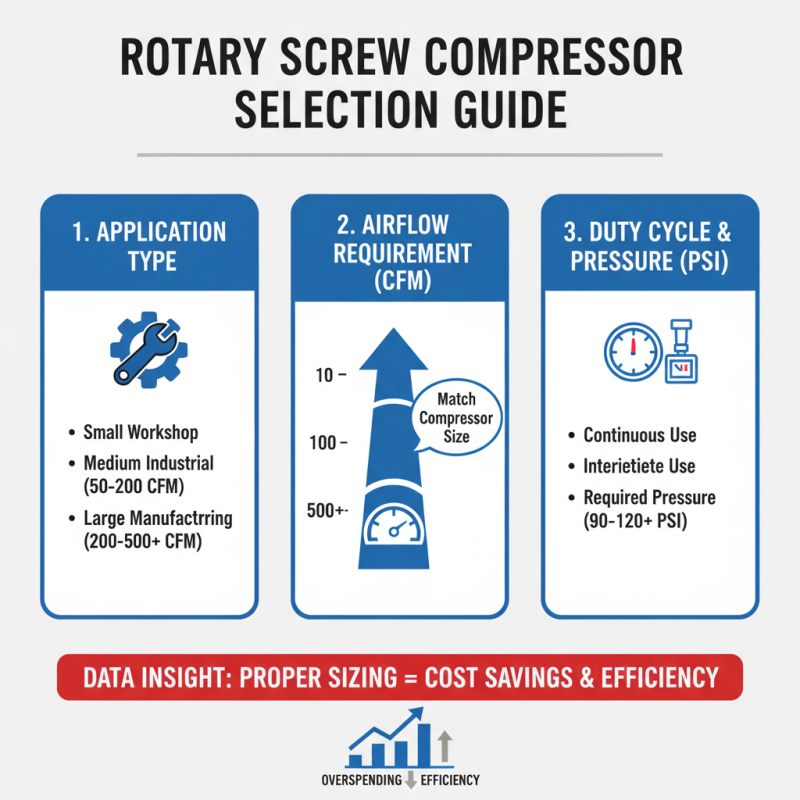

When selecting a rotary screw compressor, several key factors come into play. Understanding your application is crucial. The required air flow rate, usually measured in CFM (cubic feet per minute), determines the compressor size. For example, a small workshop might need only 10 CFM, while a large manufacturing plant could require up to 500 CFM or more. According to industry data, a gap in this assessment can lead to over-spending or inefficiency.

Next, consider the compressor’s duty cycle. Some applications demand continuous operation, while others may work intermittently. Continuous operation requires a robust machine that can handle heat buildup. In contrast, a compressor for intermittent duty can be smaller and less expensive. Surveys show that around 20% of users underestimate their duty cycle, leading to higher maintenance costs.

Energy efficiency is another key factor. Many compressors are rated by their kW output relative to their output capacity. This rating indicates energy costs. Investing in a highly efficient model can lead to savings in the long run. Data reveals that energy accounts for about 70% of the total lifecycle cost of a compressor. Overlooking energy efficiency can result in high operational costs and wasted resources.

Assessing Your Air Demand and System Requirements

Assessing your air demand is crucial when choosing a rotary screw compressor. Start by determining the total volume of air your operations require. Consider peak demand periods. A good estimate can help avoid under or over-sizing the compressor. Remember, oversizing can cause inefficiency. It may lead to higher energy costs and increased wear.

Look closely at the specific needs of your system. Do you use air tools, spray paint equipment, or run pneumatic machinery? Each application has different requirements. You'll need to assess the average and peak pressure needed. It's easy to overlook fluctuations in usage. Make a note of the adjustments your operations might need over time.

Think about the environment, too. Operating conditions affect compressor performance. High temperatures or humidity levels can change your air needs. These factors might lead to a reevaluation of your initial estimates. Sometimes, what seems adequate on paper doesn't hold up in practice. Regularly reviewing your requirements is essential to ensure efficiency.

Evaluating Energy Efficiency and Performance Ratings

When selecting a rotary screw compressor, energy efficiency is key. The U.S. Department of Energy (DOE) highlights that compressed air systems can consume up to 30% of a facility's total energy. Therefore, evaluating performance ratings is essential. Look for compressors with high energy efficiency ratings, such as the Integrated Energy Efficiency Ratio (IEER). A compressor with an IEER above 10 can significantly reduce operational costs over time.

Another aspect to consider is the compressor's operational performance under varying load conditions. A report by the Compressed Air Challenge indicates that compressors with variable speed drives can adjust their output. This adaptability leads to better energy savings, especially in fluctuating demand scenarios.

Maintenance routines also impact efficiency. Underperformance is often linked to neglected maintenance. According to the American National Standards Institute (ANSI), inefficient compressors waste 20-30% more energy when not properly maintained. Regular checks on filters and belts help preserve energy usage. Ignoring these factors can lead to costly mistakes. Investing time in understanding these ratings can make a substantial difference in your compressor choices.

Comparing Costs, Warranty, and Maintenance Options

When choosing a rotary screw compressor, consider cost, warranty, and maintenance options. The initial investment can vary widely. Some models may have a lower price but higher long-term costs. Evaluate your budget carefully. Avoid overspending on features you won't use.

Tips: Always check the warranty details. A good warranty can save money on repairs. Look for at least a 5-year coverage on major parts. This adds value to your investment.

Maintenance is key to efficiency. Regular service extends the life of the compressor. Factor in these costs. Some models require more attention than others. Consider ease of access to parts. Complicated designs may increase downtime during repairs.

Tips: Keep maintenance records. Documenting service can be useful for warranty claims. It also helps track performance issues over time. Always be proactive. A small issue now can lead to costly repairs later.

Related Posts

-

Real World Applications of Rotary Screw Air Compressors in Various Industries

-

Exploring Portable Air Compressor Innovations at the 2025 China Import and Export Fair

-

Maximize Efficiency: How a Gas Air Compressor Transforms Your Workshop Experience

-

Why You Should Shop Air Compressors: Key Features and Benefits for Optimal Performance

-

Why Choose a Desiccant Air Dryer for Optimal Moisture Control in Your System

-

Top 10 Small Air Compressors for Home and Garage Use