24 Hour Service

24 Hour Service- 800.825.3222

- Now Hiring

- Request A Quote

Blog

How to Choose the Right Air Dryer for Your Compressor Needs

When selecting the appropriate air dryer for compressor applications, it is crucial to understand both the operational requirements and the specific characteristics of various dryer types. According to the Compressed Air and Gas Institute (CAGI), nearly 70% of all compressed air systems experience moisture-related issues, leading to potential equipment damage and decreased efficiency. Compressed air systems without effective moisture control can incur costs upwards of 30% in increased energy consumption and maintenance. Moreover, a recent report by the International Journal of Compressed Air Technology indicates that the right air dryer for compressor usage can enhance system performance by up to 40%, significantly improving productivity and reliability. Therefore, understanding the different air dryer technologies, including refrigerated, desiccant, and membrane types, is essential for optimizing compressor performance and extending the lifespan of pneumatic tools and machinery.

Understanding Compressed Air Quality: Industry Standards and Moisture Content Metrics

Compressed air quality is essential for ensuring the longevity and efficiency of equipment in various industries. Industry standards, such as ISO 8573, provide a framework to measure and classify the quality of compressed air. This standard outlines the acceptable levels of particulate matter, water content, and oil contamination, helping organizations understand the necessary parameters they must meet for their specific applications. For example, a factory dealing with sensitive electronics may need air with minimal moisture and contamination, while a workshop might have more lenient requirements.

Moisture content is a critical metric in assessing compressed air quality, as excessive moisture can lead to corrosion, equipment failure, and operational inefficiencies. It is commonly measured in parts per million (PPM) or as a dew point temperature. Understanding these metrics allows businesses to select the appropriate air dryer to eliminate moisture effectively. Depending on the application, some may require desiccant dryers for low dew points, while others may benefit from refrigerated dryers that provide adequate moisture removal for less sensitive uses. Choosing the right air dryer based on these criteria ensures optimal performance and reliability of the compressed air system.

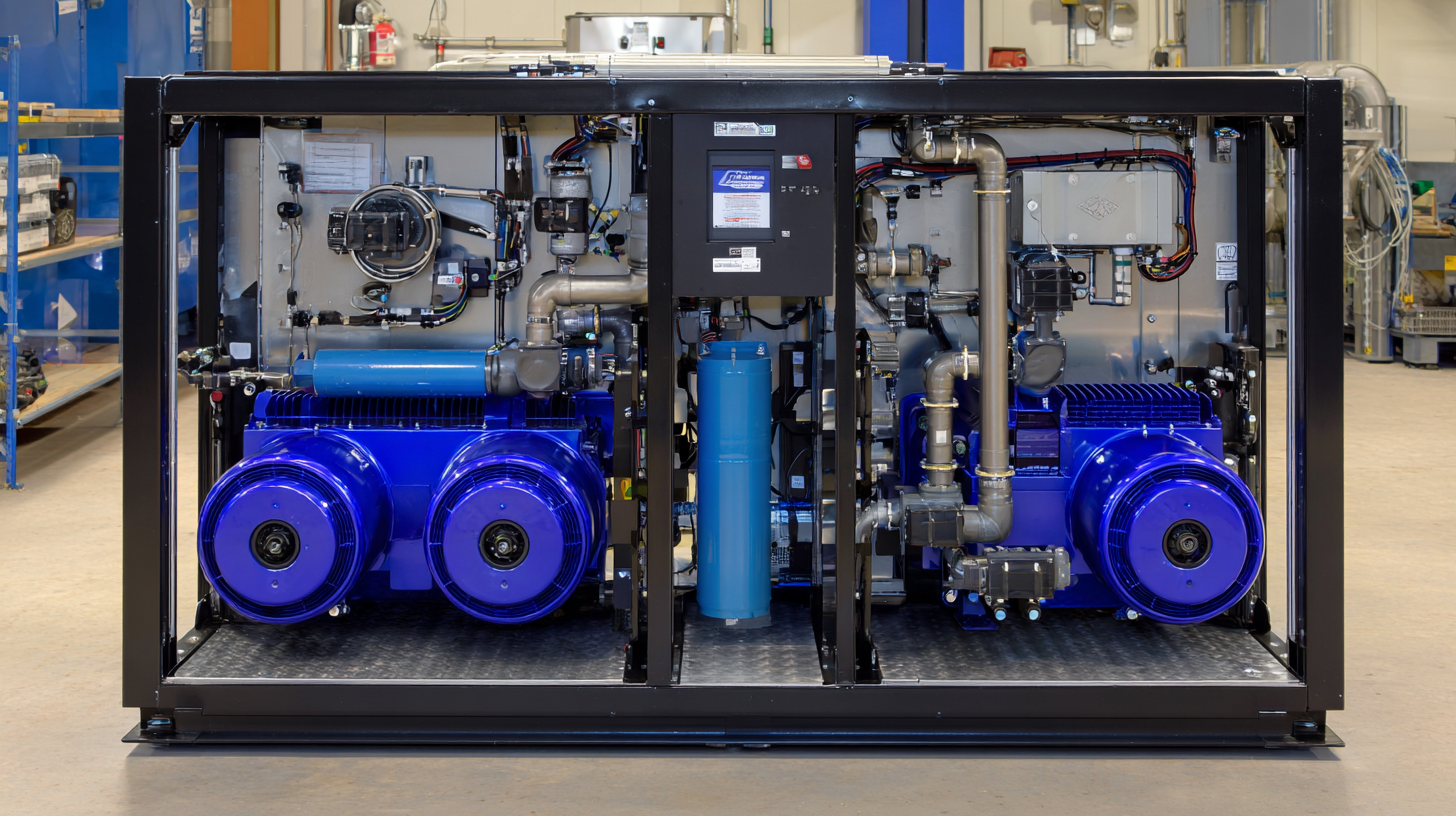

Types of Air Dryers: Comparing Refrigerated, Desiccant, and Membrane Options

When selecting an air dryer for your compressor needs, understanding the different types available is crucial. Refrigerated air dryers are one of the most common options. They cool the compressed air to condense water vapor, which is then removed through a drainage system. This type of dryer is efficient for maintaining a consistent temperature and is ideal for applications that require a basic level of dryness without excessive investment.

In contrast, desiccant air dryers use a different method by absorbing moisture from the air. They contain materials like silica gel or activated alumina that extract water vapor, making them highly effective in providing extremely dry air. These are particularly suitable for applications requiring low dew points, such as in the food and pharmaceutical industries, where moisture can cause product spoilage or equipment damage. Lastly, membrane air dryers utilize semi-permeable membranes to separate moisture from compressed air. They are often compact and require minimal maintenance, making them a great choice for mobile applications or small operations where space is at a premium.

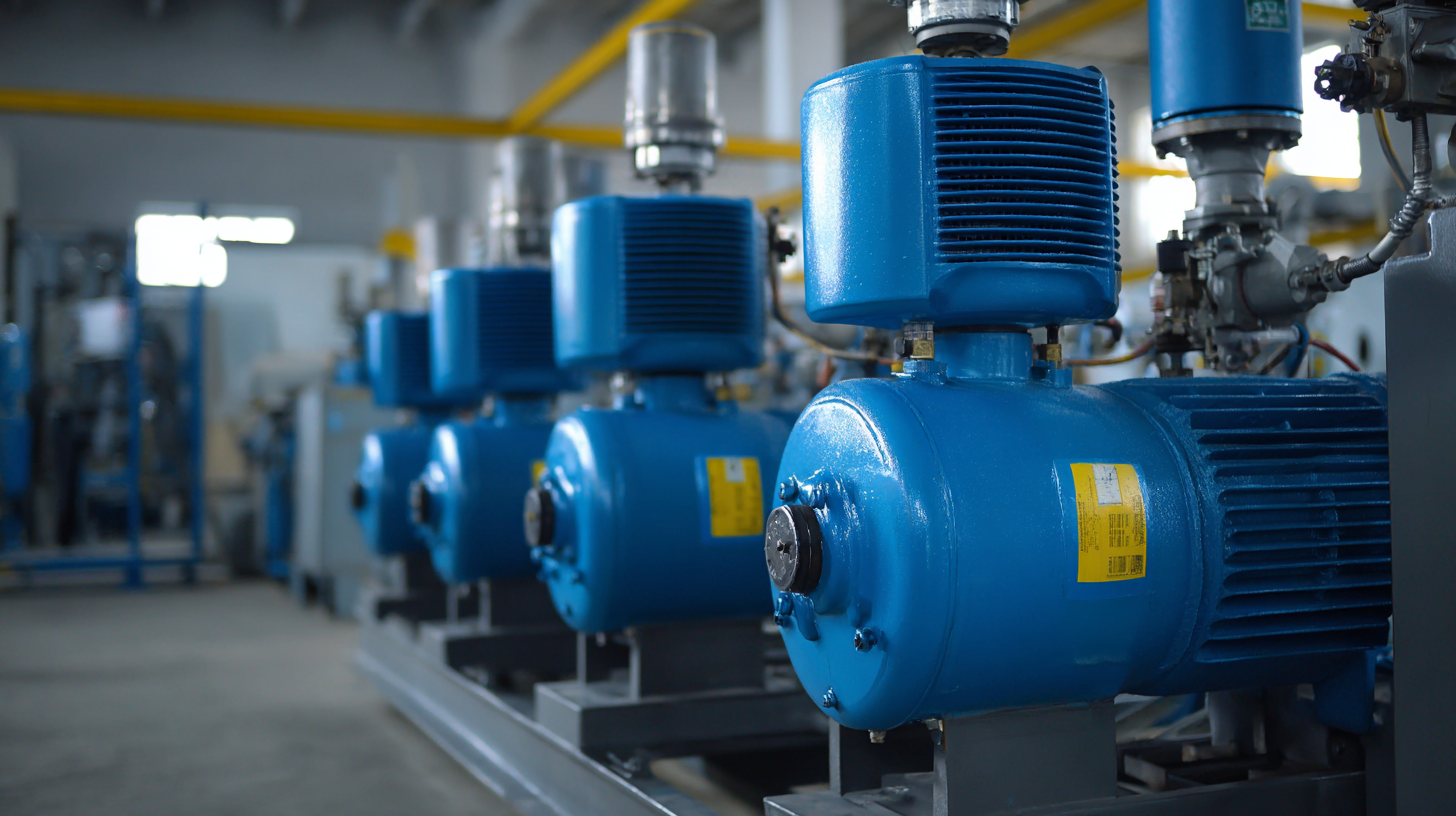

Sizing Your Air Dryer: Calculating the Flow Rate and Pressure Drop Requirements

When selecting the right air dryer for your compressor system, understanding the flow rate and pressure drop requirements is essential. The flow rate, measured in cubic feet per minute (CFM), indicates the volume of air your system will require. To determine the necessary flow rate, consider the total demand of all tools and equipment that will be used simultaneously. It's crucial to account for potential surges or peak usage periods where more air may be needed than usual. Ideally, your air dryer should be rated for a flow rate that accommodates this maximum demand, ensuring optimal performance throughout its operation.

Equally important is calculating the allowable pressure drop in your system. Pressure drop refers to the reduction in air pressure as it moves through the air dryer and is significant because it can affect the performance of your pneumatic tools and processes. Generally, a pressure drop of 2 to 5 psi is acceptable for most applications. However, if your operational requirements are strict, you may need to choose a dryer designed to minimize pressure loss. By carefully evaluating both the flow rate and pressure drop, you can make an informed decision that ensures efficient and reliable performance from your air compressor system.

How to Choose the Right Air Dryer for Your Compressor Needs

| Air Dryer Type | Flow Rate (CFM) | Max Pressure Drop (psi) | Operating Temperature (°F) | Approximate Cost ($) |

|---|---|---|---|---|

| Refrigerated Air Dryer | 25 | 5 | 35 to 50 | 800 |

| Desiccant Air Dryer | 10 | 7 | 40 to 110 | 1200 |

| Membrane Air Dryer | 15 | 3 | 0 to 100 | 500 |

| Cyclone Separator | 20 | 2 | 50 to 120 | 300 |

Energy Efficiency in Air Dryers: Evaluating CFM, kW Usage, and Cost Savings

When selecting an air dryer for your compressor needs, energy efficiency should be at the forefront of your decision-making process. The performance of an air dryer can be evaluated through critical parameters such as Cubic Feet per Minute (CFM) and kilowatt (kW) usage. According to a report by the Compressed Air and Gas Institute, poorly sized or inefficient air dryers can lead to energy costs exceeding $2,000 annually per dryer. Therefore, understanding your compressor's CFM requirements can optimize system performance and minimize unnecessary energy expenditure.

When selecting an air dryer for your compressor needs, energy efficiency should be at the forefront of your decision-making process. The performance of an air dryer can be evaluated through critical parameters such as Cubic Feet per Minute (CFM) and kilowatt (kW) usage. According to a report by the Compressed Air and Gas Institute, poorly sized or inefficient air dryers can lead to energy costs exceeding $2,000 annually per dryer. Therefore, understanding your compressor's CFM requirements can optimize system performance and minimize unnecessary energy expenditure.

In addition to evaluating CFM, considering the kW usage of various air dryer models is essential for predicting ongoing operational costs. Research indicates that energy-efficient dryers can save up to 30% on energy bills compared to standard models. For instance, a high-efficiency heatless desiccant dryer can use as little as 3.5 kW at peak performance, whereas traditional dryers might consume over 5 kW for the same output. By opting for an energy-efficient air dryer, businesses not only reduce their carbon footprint but can also realize significant cost savings over time, illustrating the importance of thoughtful investment in air drying technology.

Maintenance Tips: Ensuring Optimal Performance and Longevity of Your Air Dryer

Maintaining your air dryer is essential for ensuring its optimal performance and longevity. Regularly checking the filters is one of the most crucial maintenance tasks. Clean or replace the filters as per the manufacturer's recommendations to prevent dust and debris from obstructing airflow, which can lead to inefficient operation or even break down. Additionally, inspecting the condensate drain for blockages can help avoid water accumulation, reducing the risk of corrosion and damage to the system.

Another key aspect of maintenance involves monitoring the dryer’s operating temperature and pressure. Keep an eye on the gauges to ensure they are within the specified range. If the readings are consistently higher or lower than normal, it may indicate an underlying issue that requires attention. Lubricating any moving parts and tightening loose connections can also prevent premature wear and improve the dryer’s efficiency. By implementing these maintenance tips, you can significantly enhance the lifespan of your air dryer and maintain the performance of your compressor system.

Air Dryer Performance Comparison

Related Posts

-

Unique Examples of Air Dryer Solutions for Compressors

-

Common Issues Faced When Choosing Air Dryers for Compressors

-

The Definitive Ultimate Guide to Choosing the Right Desiccant Air Dryer for Your Needs

-

7 Essential Features of the Best Portable Air Compressors for Every Home

-

Ultimate Guide to Understanding Air Compressor Parts for Optimal Performance

-

Understanding the Challenges Faced by Global Buyers in Sourcing Desiccant Air Dryers