24 Hour Service

24 Hour Service- 800.825.3222

- Now Hiring

- Request A Quote

Blog

Top 10 Best Refrigerated Air Dryers for Your Industrial Needs

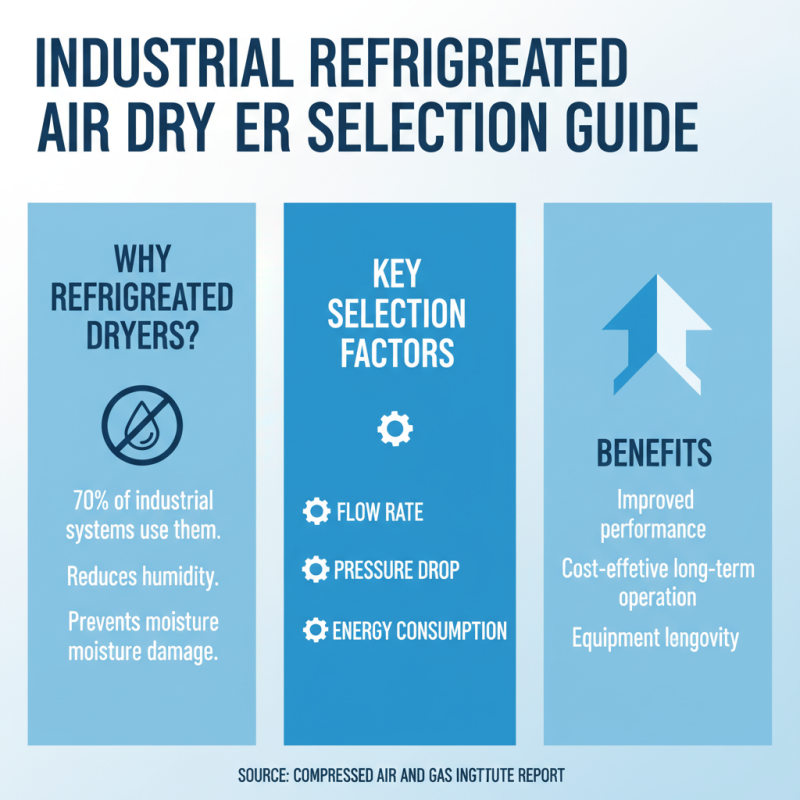

In the industrial sector, maintaining optimal air quality is crucial for the efficient operation of pneumatic systems. Refrigerated air dryers play a vital role in this process by effectively removing moisture from compressed air, which prevents corrosion and enhances the longevity of equipment. According to a recent report by the Compressed Air and Gas Institute (CAGI), approximately 70% of all compressed air systems experience moisture-related issues, leading to significant downtime and costly repairs. This underscores the importance of selecting the right refrigerated air dryer to ensure reliable performance in critical applications.

With an increasing emphasis on energy efficiency and cost-effectiveness, the demand for high-quality refrigerated air dryers is on the rise. Industry projections indicate that the market for compressed air treatment equipment, including dryers, is expected to grow at a CAGR of 5.2% through 2025, driven by the need for sustainable solutions in manufacturing environments. In this context, identifying the top models available not only facilitates better decision-making but also ensures that industrial operations can run smoothly and efficiently. By exploring the top 10 best refrigerated air dryers tailored for industrial needs, we aim to equip professionals with the insights necessary for optimizing their compressed air systems.

Understanding Refrigerated Air Dryers and Their Importance

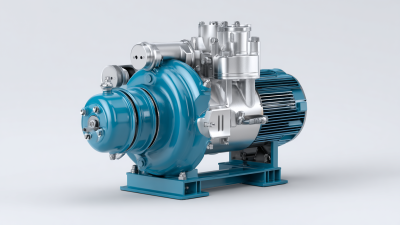

Refrigerated air dryers are essential components in industrial compressed air systems, ensuring the delivery of dry, clean air for various applications. By utilizing a refrigeration cycle, these dryers cool the compressed air, condensing moisture into liquid water, which is then expelled from the system. This process is critical in preventing corrosion, freezing, and other issues that can arise from excess moisture, which could lead to equipment failures and increased maintenance costs. According to the Compressed Air and Gas Institute, a properly maintained refrigerated air dryer can reduce energy expenditures by up to 20%, highlighting their importance in operational efficiency.

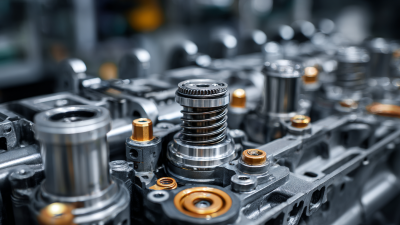

The significance of refrigerated air dryers extends beyond just moisture removal. They play a pivotal role in maintaining the quality of pneumatic tools and processes, especially in manufacturing industries where clean air is vital. A study by the U.S. Department of Energy indicates that improper treatment of compressed air, including the lack of appropriate drying, can lead to significant losses, estimating that businesses could save approximately $1.5 billion annually by optimizing their air systems. Thus, investing in a high-quality refrigerated air dryer not only enhances performance but also contributes to long-term cost savings and reliability in industrial operations.

Top 10 Best Refrigerated Air Dryers for Your Industrial Needs

| Model | Cooling Capacity (CFM) | Power Consumption (kW) | Operating Temperature (°F) | Weight (lbs) | Price Range (USD) |

|---|---|---|---|---|---|

| Model A | 50 CFM | 5.5 kW | 35 - 50°F | 150 lbs | $1,200 - $1,500 |

| Model B | 100 CFM | 7.0 kW | 35 - 45°F | 200 lbs | $1,800 - $2,200 |

| Model C | 150 CFM | 9.5 kW | 40 - 55°F | 250 lbs | $2,500 - $3,000 |

| Model D | 200 CFM | 11.0 kW | 30 - 50°F | 300 lbs | $3,200 - $3,800 |

| Model E | 250 CFM | 14.0 kW | 35 - 60°F | 350 lbs | $3,800 - $4,500 |

| Model F | 300 CFM | 16.0 kW | 40 - 65°F | 400 lbs | $4,500 - $5,000 |

| Model G | 350 CFM | 18.5 kW | 35 - 70°F | 450 lbs | $5,000 - $6,000 |

| Model H | 400 CFM | 20.0 kW | 30 - 75°F | 500 lbs | $6,000 - $7,000 |

| Model I | 450 CFM | 25.0 kW | 30 - 80°F | 600 lbs | $7,500 - $8,500 |

| Model J | 500 CFM | 28.0 kW | 25 - 85°F | 700 lbs | $8,500 - $10,000 |

Key Features to Consider When Selecting an Industrial Air Dryer

When selecting an industrial air dryer, there are several key features to consider that can significantly impact efficiency and performance. One of the most crucial aspects is the drying capacity of the unit, which should match or exceed the air demand of your application. A dryer with insufficient capacity can lead to moisture buildup, potentially damaging equipment and affecting product quality. Additionally, it is essential to evaluate the dew point of the dryer, as a lower dew point will ensure that air is kept dry even in varying weather conditions.

Another important feature is the energy efficiency of the air dryer. Look for models equipped with advanced heat exchangers and variable speed controls to minimize energy consumption. This not only reduces operating costs but also promotes sustainability within your industrial processes. Moreover, consider the maintenance requirements of the dryer; a unit designed for easy servicing can help minimize downtime and ensure long-lasting performance. Combining these features will help you select the best refrigerated air dryer to meet your industrial needs effectively.

Top 10 Reviewed Refrigerated Air Dryers for Industrial Applications

When selecting a refrigerated air dryer for industrial applications, it's crucial to consider the specific requirements of your operations. According to a report by the Compressed Air and Gas Institute, nearly 70% of all industrial air systems use refrigerated dryers due to their efficiency in reducing humidity levels and preventing moisture-related damage. Key factors such as flow rate, pressure drop, and energy consumption metrics should be examined, as these elements significantly influence the overall performance and cost-effectiveness of the dryer in long-term applications.

When evaluating your options, keep in mind these essential tips. First, prioritize dryers with advanced heat exchange technology, as these models can achieve higher energy efficiency ratings, reducing operational costs. Additionally, look for units with integrated controls and monitoring features; these can notify you of any maintenance needs, ensuring optimal performance and minimizing downtime. Lastly, assess the manufacturer’s support and warranty options, as reliable service can provide peace of mind and enhance the longevity of your investment. By carefully considering these factors, you can select the best refrigerated air dryer tailored to your industrial needs.

Comparative Analysis of Performance and Efficiency of Leading Models

When selecting refrigerated air dryers for industrial applications, a comparative analysis of performance and efficiency across leading models is essential. Research indicates that effective air dryers can significantly enhance system performance by optimizing compressed air quality and reducing moisture levels. According to industry reports, top-performing dryers exhibit a drying capacity of up to 200 CFM, with energy efficiency ratings reaching 95% or higher. Such metrics allow businesses to lower operational costs while maintaining air quality standards.

In a recent study examining various models, parameters such as airflow, pressure drop, and power consumption were rigorously evaluated. For instance, advanced models that incorporate innovative heat exchanger designs demonstrated enhanced thermal efficiency and reduced energy usage. This is similar to findings in other sectors, such as AI technology, where performance optimization leads to significant reductions in operational discrepancies. By leveraging comparative evaluations, industries can select air dryers that not only fulfill their immediate needs but also align with broader efficiency goals, ultimately driving productivity and sustainability in an increasingly competitive market.

Performance Comparison of Top Refrigerated Air Dryers

Maintenance Tips for Prolonging the Lifespan of Air Dryers

When it comes to maintaining the efficiency of refrigerated air dryers, regular maintenance plays a crucial role in prolonging their lifespan. One essential tip is to routinely inspect and replace filters. Clogged filters can restrict airflow, leading to increased energy consumption and reduced performance. By ensuring that filters are clean, you not only enhance the efficiency of the dryer but also prevent unnecessary wear and tear on internal components.

Another key maintenance tip is to regularly drain the condensate from the air dryer. Accumulated water can lead to corrosion and other issues that compromise the system's functionality. Implementing a schedule for draining—a daily or weekly routine depending on usage—can help in maintaining optimal performance. Additionally, consider monitoring the temperature settings regularly; appropriate temperature settings can significantly affect the dryer’s efficiency and longevity.

Lastly, always check for any leaks in the air delivery system. Leaks can lead to a significant loss of compressed air, making the dryer work harder than necessary. By promptly repairing any identified leaks, you can ensure that the air dryer operates efficiently while extending its operational life. Regularly scheduled maintenance should become a standard practice to keep your refrigerated air dryer running at peak performance.

Related Posts

-

Understanding the Challenges Faced by Global Buyers in Sourcing Desiccant Air Dryers

-

Understanding the Impact of Quality Compressor Parts on Industrial Efficiency and Maintenance Costs

-

7 Essential Features of the Best Portable Air Compressors for Every Home

-

Unique Examples of Air Dryer Solutions for Compressors

-

How to Maximize Efficiency with a Rotary Vane Vacuum Pump in Your Operations

-

How to Choose the Right Air Dryer for Your Compressor Needs