24 Hour Service

24 Hour Service- 800.825.3222

- Now Hiring

- Request A Quote

Blog

What is an Air Compressor Water Separator and How Does It Work

An air compressor water separator is a crucial component in various pneumatic systems, ensuring optimal performance and longevity of air-powered tools and machinery. As compressed air is generated, it often carries moisture that can lead to corrosion, rust, and operational inefficiencies. Understanding how an air compressor water separator functions is essential for anyone working with compressed air systems.

These separators utilize different mechanisms, such as gravity, coalescing filters, or centrifugal forces, to effectively remove water and impurities from compressed air. By doing so, they maintain the quality of the air and protect downstream equipment from damage. Additionally, employing an air compressor water separator can enhance productivity and reduce maintenance costs over time. In this guide, we will explore the working principles of air compressor water separators, their importance in maintaining the integrity of compressed air systems, and the various types available in the market to meet different industrial needs.

What is an Air Compressor Water Separator?

An air compressor water separator is an essential component designed to remove moisture from compressed air systems. When air is compressed, the temperature and pressure increase, which causes water vapor to condense into liquid form. According to the Compressed Air and Gas Institute (CAGI), an estimated 90% of compressed air systems have some degree of moisture contamination, which can lead to corrosion, equipment failure, and reduced efficiency.

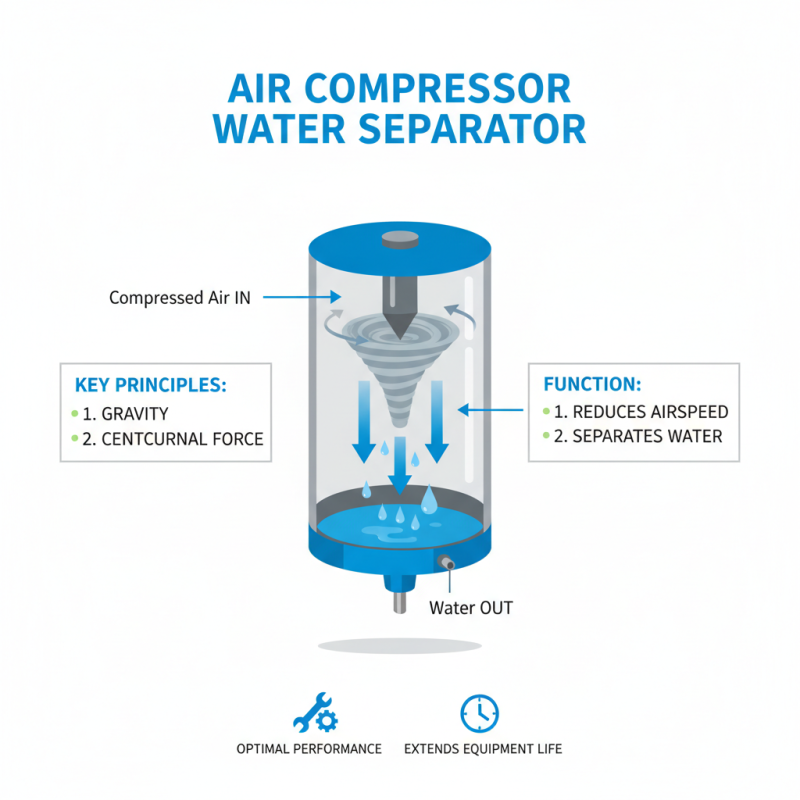

The operation of a water separator relies on the principle of gravity and centrifugal force. As compressed air enters the separator, it enters a chamber where the velocity of the air is slowed down, allowing water droplets to fall into a collection reservoir. The CAGI reports that a properly functioning water separator can significantly reduce moisture content in the air, often by up to 99%, thereby extending the lifespan of downstream equipment and improving the quality of the compressed air being delivered for various applications. Regular maintenance of the separator is crucial to ensure optimal performance and reliability, particularly in industrial environments where air quality is paramount.

The Purpose of Water Separators in Air Compressors

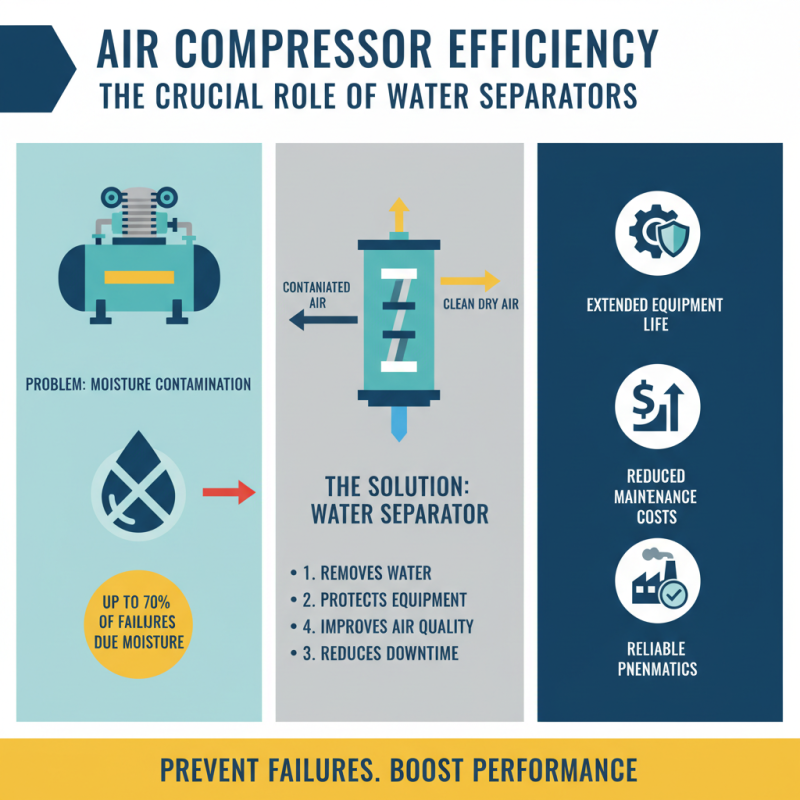

Water separators play a crucial role in the operation of air compressors, primarily aimed at removing moisture from the compressed air. According to industry reports, up to 70% of hydraulic and pneumatic failures can be attributed to moisture contamination. This makes the implementation of a reliable water separator essential for maintaining air quality and preventing damage to equipment.

The purpose of water separators is to ensure that the compressed air remains dry, which is vital for various industrial processes. When air is compressed, the temperature rises, leading to moisture condensation. If this moisture is not effectively removed, it can cause corrosion, inhibit the performance of tools, and lead to costly repairs. By integrating a water separator into the air compression system, operators can achieve a significant increase in the lifespan of air-powered tools and machinery.

Tips: Regular maintenance of your air compressor and water separator is essential. Check for any signs of water accumulation and clear the separator regularly to ensure optimal performance. Additionally, consider monitoring the humidity levels in your work environment to further understand the moisture content in compressed air and make necessary adjustments to your separator system. This proactive approach can save time and resources in the long run.

How Air Compressor Water Separators Function Mechanically

Air compressor water separators are essential components designed to remove moisture from compressed air systems, ensuring optimal performance and longevity of the equipment. Mechanically, these separators function by utilizing the principles of gravity and centrifugal force. As compressed air enters the separator, it is routed through a specially designed chamber. The design promotes a reduction in airspeed, allowing water droplets, which are heavier than air, to settle at the bottom of the separator.

Once the moisture condenses, it is collected in a reservoir or trap, where it can be drained periodically. Some advanced separators may incorporate additional filtration elements to capture finer water particles and contaminants. Additionally, various designs may utilize baffles or vanes that enhance the swirling action, further improving the separation efficiency. By effectively removing water from the compressed air, these separators prevent equipment corrosion, enhance product quality, and reduce maintenance costs, making them vital for any compressed air application.

Common Types of Air Compressor Water Separators

Air compressor water separators are crucial for maintaining the efficiency and longevity of pneumatic systems. They are designed to remove excess moisture from the compressed air, which can otherwise lead to corrosion, contamination, and malfunctions. There are several common types of water separators used in the industry, each serving a specific need based on system requirements and design.

One prevalent type is the coalescing separator, which uses a series of filters to capture and combine tiny water droplets, forming larger ones that can be easily removed. Studies indicate that a well-functioning coalescing separator can reduce water in the compressed air by up to 99%. Another effective option is the centrifugal separator, which utilizes centrifugal force to fling water droplets away from the air stream. This type is often preferred in situations where high volumes of air are processed quickly, as it can handle significant moisture loads efficiently.

Tips: Regular maintenance of your water separator is key to ensuring optimal performance. Check and replace filters as recommended, and consider implementing a moisture control system that includes regular drainage of the separator. Additionally, monitor the dew point of your compressed air regularly; keeping it below the ambient temperature will significantly reduce moisture accumulation in your system.

Maintenance Tips for Ensuring Effective Water Separation

Maintaining an air compressor water separator is crucial to ensure optimal performance and longevity of the equipment. Regular maintenance not only enhances efficiency but also extends the lifespan of the air compressor system. According to industry reports, over 30% of compressed air systems experience issues related to moisture, leading to decreased productivity and increased energy costs. Therefore, keeping the water separator in prime condition can significantly mitigate these risks.

One effective maintenance tip involves regularly checking and replacing the filters within the water separator. Filters should be inspected at least once a month, and changes should be made based on the manufacturer’s recommendations or when the filter indicator shows that it’s time for a replacement. Additionally, it’s vital to drain the separators to remove accumulated moisture. Many industry experts recommend daily drainage for systems operating in high-humidity environments. Implementing a routine maintenance schedule can lead to a noticeable reduction in moisture-related complications, ensuring your compressed air system operates efficiently.

Another important aspect of maintenance is monitoring the separator's performance. Keeping an eye on pressure levels and moisture content is essential. A drop in pressure may indicate a blockage or a malfunctioning separator, which can lead to moisture intrusion. Regular performance checks can be complemented by using diagnostic tools, which are increasingly available in the market. Industry data suggests that companies that adhere to strict maintenance routines can see a reduction in downtime by up to 22%, demonstrating the profound impact effective water separation has on operational efficiency.

Water Separator Efficiency in Air Compressors

This bar chart illustrates the water separation efficiency in air compressors at different separation levels. As the separation levels increase, the efficiency of water separation also improves, demonstrating the importance of maintaining air compressor systems for optimal performance.

Related Posts

-

Unique Examples of Air Dryer Solutions for Compressors

-

How to Select the Right Air Dryer for Your Compressor Needs

-

Understanding the Impact of Quality Compressor Parts on Industrial Efficiency and Maintenance Costs

-

Top 10 Best Refrigerated Air Dryers for Your Industrial Needs

-

Common Issues Faced When Choosing Air Dryers for Compressors

-

How to Maximize Efficiency with a Rotary Vane Vacuum Pump in Your Operations