24 Hour Service

24 Hour Service- 800.825.3222

- Now Hiring

- Request A Quote

Blog

Expert Guide to Affordable Air Compressor Repair Techniques for Homeowners

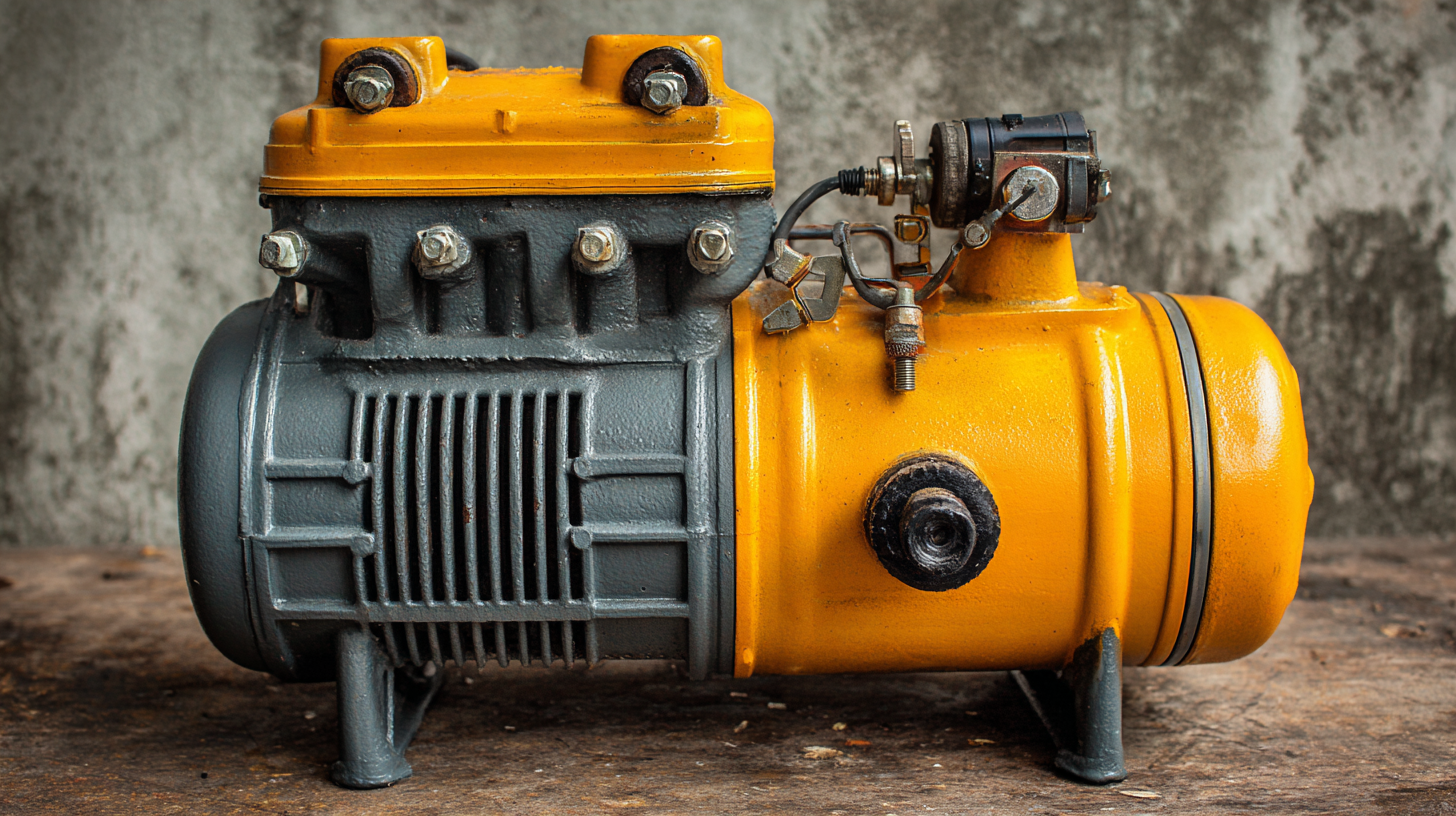

In the realm of home maintenance, air compressor repair stands as a crucial skill for homeowners seeking to extend the longevity and efficiency of their equipment. According to a report by the Professional Heating and Plumbing Contractor (PHPC), nearly 70% of air compressor failures are attributed to improper maintenance and minor repair issues that could easily be resolved by homeowners. This underscores the importance of understanding basic repair techniques, which can save both time and money in the long run.

Furthermore, a survey conducted by the Air-Conditioning, Heating, and Refrigeration Institute (AHRI) reveals that homeowners can reduce their repair costs by up to 50% by mastering DIY repair strategies. This expert guide aims to equip homeowners with affordable air compressor repair techniques, empowering them to tackle common problems effectively while enhancing their overall home repair skills.

Furthermore, a survey conducted by the Air-Conditioning, Heating, and Refrigeration Institute (AHRI) reveals that homeowners can reduce their repair costs by up to 50% by mastering DIY repair strategies. This expert guide aims to equip homeowners with affordable air compressor repair techniques, empowering them to tackle common problems effectively while enhancing their overall home repair skills.

Understanding Common Air Compressor Issues and Their Causes

When it comes to air compressor maintenance, understanding common issues and their causes is essential for homeowners. One frequent problem is a lack of air pressure, often due to leaks in the hose or fittings. These leaks can hinder performance and efficiency. Another prevalent issue is an overheating compressor, which can result from excessive use or insufficient lubrication. Overheating not only disrupts functionality but can also lead to more severe damage if not addressed promptly.

Tips: To prevent leaks, regularly inspect your air hoses and connections for wear and tear. Using a soap solution can help identify small leaks, making repairs easier. Additionally, always check the oil level in your compressor to ensure it’s adequately lubricated, as this helps prevent overheating.

Another common problem is a tripped circuit breaker or blown fuse, frequently caused by the compressor drawing too much power during startup. This can signify an electrical issue or an overloaded circuit. Make sure to operate your compressor on a dedicated circuit and consider using a surge protector.

Tips: To avoid electrical problems, check the compressor’s power requirements and make sure your circuit can handle the load. If the issues persist, it may be wise to consult with a professional to ensure your compressor is in optimal working condition.

Step-by-Step Guide to Diagnosing Air Compressor Problems at Home

Diagnosing air compressor problems at home can seem daunting, but with a systematic approach, homeowners can tackle common issues effectively. Start by checking for obvious signs of trouble, such as unusual noises or leaks. A visual inspection of the compressor unit can reveal loose fittings or cracked hoses. Listening for strange sounds is equally important; a knocking noise may indicate a mechanical failure, while frequent, excessive cycling could signal an issue with the thermostat or pressure switch.

Once you've identified potential symptoms, proceed to test the electrical components. Begin by ensuring that the compressor is receiving power and that all connections are secured. If the compressor fails to start, a faulty capacitor might be to blame. Additionally, examine the pressure gauge for accuracy; this can help ascertain whether the unit is building pressure properly. Regular maintenance tasks, such as replacing air filters and draining moisture from the tank, can prevent future breakdowns and enhance the longevity of your air compressor. By following these steps, homeowners can efficiently diagnose and address air compressor issues, ensuring reliable performance when needed.

Essential Tools and Parts for DIY Air Compressor Repairs

When tackling air compressor repairs at home, having the right tools and parts is essential for an effective DIY approach. According to a report by the American Society of Mechanical Engineers, over 65% of homeowners who attempt air compressor repairs find that access to proper tools directly affects the outcome of the repair. Key tools such as wrenches, screwdrivers, and pliers are fundamental, but investing in a quality multimeter can provide valuable insights into electrical issues, ensuring troubleshooting is both efficient and accurate.

In terms of parts, replacement components like belts, gaskets, and filters are often needed. A survey from the International Air Compressor Manufacturers Association indicates that nearly 70% of air compressor failures are related to worn-out parts. Homeowners should consider sourcing OEM (original equipment manufacturer) parts to maintain the integrity and performance of their machines. Websites specializing in compressor parts typically offer comprehensive guides, ensuring homeowners have access to the correct specifications and compatibility details for their repairs. By equipping themselves with the right tools and parts, homeowners can confidently undertake air compressor repairs, ultimately saving time and money.

Cost-Effective Techniques to Fix Air Compressors without Professional Help

When it comes to fixing air compressors without professional help, homeowners can employ several cost-effective techniques that maximize efficiency while minimizing expenses. One of the first steps in repair is to conduct a thorough leak detection process. This not only reduces compressed air waste by up to 50% but also simplifies further repairs by identifying the root cause of inefficiencies. Maintaining proper seals and promptly repairing any leaks can lead to significant energy savings and lower operational costs.

Another technique is regular maintenance, which includes checking and changing air filters, inspecting hoses for wear, and keeping the compressor clean. A well-maintained air compressor runs more efficiently, reducing the likelihood of expensive repairs. Additionally, utilizing DIY troubleshooting guides can empower homeowners to tackle common issues themselves, from replacing faulty pressure switches to re-tuning pressure settings for optimal performance. These practices cultivate self-sufficiency while ensuring that compressors operate at peak efficiency without incurring hefty repair bills.

Maintaining Your Air Compressor: Tips for Long-Term Efficiency and Longevity

Maintaining your air compressor is crucial for ensuring its long-term efficiency and longevity. Regular care not only extends the life of the equipment but also enhances its performance, making it an essential tool in any homeowner's garage. To kick off your maintenance routine, start with a consistent inspection schedule—checking the air filter, oil level, and belts regularly can help catch issues before they escalate.

One of the most effective tips for maintaining your air compressor is to keep it clean and free from debris. Dust and dirt can clog filters and reduce airflow, leading to overheating and diminished efficiency. Additionally, remember to drain the tank regularly to remove accumulated moisture. This prevents rusting and corrosion, which can cause significant damage over time.

Finally, lubricating moving parts is essential for a smoothly operating air compressor. Using manufacturer-recommended oil will keep the motor and pump functioning efficiently. Periodic checks and refills will ensure your air compressor runs like new, reducing the risk of breakdowns and costly repairs in the future.

Related Posts

-

How to Choose the Right Air Compressor Pump for Your Specific Needs

-

Common Issues Faced When Choosing Air Dryers for Compressors

-

How to Choose the Right Air Dryer for Your Compressor Needs

-

Real World Applications of Rotary Screw Air Compressors in Various Industries

-

Unique Examples of Air Dryer Solutions for Compressors

-

Navigating the 2025 Landscape of Best Rotary Screw Compressors and Their Impact on Global Procurement