24 Hour Service

24 Hour Service- 800.825.3222

- Now Hiring

- Request A Quote

Blog

2026 Best Gas Compressor Reviews and Buying Guide?

When searching for a reliable gas compressor, it’s essential to consider various factors. A gas compressor plays a vital role in numerous applications. These can include industrial use, automotive services, and HVAC systems. Choosing the right model can significantly impact efficiency and performance.

In this guide, we will explore the best gas compressors of 2026. You'll find comprehensive reviews highlighting key features, advantages, and drawbacks. Understanding these details will help you make an informed decision. But bear in mind, not all compressors are created equal. What works for one situation may not suit another.

Some compressors may perform well initially, but can falter under heavy use. It’s crucial to think about the long-term reliability of your choice. Moreover, user feedback often reveals imperfections not immediately apparent. We hope this buying guide aids you in selecting the perfect gas compressor for your needs.

Overview of Gas Compressors: Types and Applications

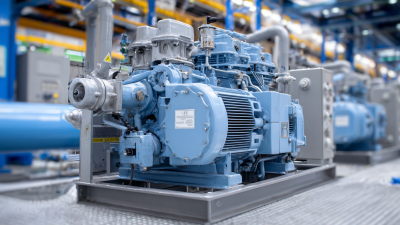

Gas compressors are vital in various industries. They are used to increase the pressure of gas for storage, transport, or use. Different types of gas compressors serve specific applications. Understanding these types is essential for making informed choices.

There are several types of gas compressors. Positive displacement compressors work by trapping a fixed volume of gas and reducing its volume. These are commonly used in small-scale applications. Dynamic compressors, on the other hand, compress gas using high-speed rotating parts. They are more suitable for large-scale operations. When selecting a gas compressor, consider the required pressure and the type of gas being used.

In practice, choosing the right compressor can be challenging. Users must evaluate airflow needs and efficiency. Sometimes, the best choice is not clear-cut. It may involve trade-offs between size, cost, and capacity. Users should thoroughly analyze their needs to avoid costly mistakes. This process can be rather complex. Always reflect on the operational environment, as it plays a significant role in compressor performance.

Key Features to Consider When Buying a Gas Compressor

When shopping for a gas compressor, several key features are essential to ensure you make the right choice. Power output is crucial, especially if you plan to use the compressor for heavy-duty applications. Look for models with adequate horsepower ratings matching your needs. The industry standard indicates that most workshops require at least 5-7 HP for efficient operation.

Airflow capacity is another vital aspect. Measured in cubic feet per minute (CFM), this determines how quickly the compressor can deliver air. A CFM rating of 10-20 is often sufficient for basic tools, while more complex tasks may require levels above 30 CFM. It's crucial to assess your specific requirements to avoid undersizing your equipment.

Tips: Always consider the tank size. A larger tank can store more air and provide longer run times without the compressor cycling frequently. Additionally, check the noise levels; compressors can be quite loud. Opting for a quieter model might save you from future headaches.

Don't overlook portability. If you need to move your compressor frequently, lightweight models with wheels can be a game-changer. Remember, a good gas compressor should balance power, capacity, and ease of use. Failing to reflect on these can lead to frustration down the road.

Top 2026 Gas Compressors: Performance and Value Comparisons

In 2026, gas compressors are critical for various industries. They enhance efficiency and fuel management. According to recent industry reports, the global gas compressor market was valued at over $14 billion in 2022 and is expected to grow significantly. This growth indicates a demand for high-performance compressors that offer optimal value for their cost.

When evaluating gas compressors, it’s essential to focus on performance metrics. Reliable data shows that compressors can vary widely in efficiency. For instance, machines with variable speed drives tend to consume 20-30% less energy than standard units. Yet, not all compressors offer this technology. Consumers must assess their needs carefully. It’s also vital to understand maintenance needs. Some compressors require frequent servicing, impacting overall operational costs.

Value assessment is equally crucial. Initial price does not always reflect long-term investment. A cheaper model may lead to higher repair costs later. On the flip side, premium models might underperform if not suitable for specific applications. Thus, weighing upfront costs against potential savings becomes necessary. Users may often overlook these factors, leading to regretful choices in the long run.

2026 Best Gas Compressor Reviews and Buying Guide

| Model | Performance (HP) | Max Pressure (PSI) | Tank Size (Gallon) | Noise Level (dB) | Price ($) |

|---|---|---|---|---|---|

| Gas Compressor A | 5 | 150 | 10 | 75 | 599 |

| Gas Compressor B | 7 | 175 | 12 | 70 | 849 |

| Gas Compressor C | 6 | 160 | 8 | 80 | 699 |

| Gas Compressor D | 8 | 200 | 15 | 65 | 949 |

| Gas Compressor E | 4 | 140 | 7 | 85 | 499 |

Maintenance Tips for Longevity of Your Gas Compressor

Proper maintenance is crucial for enhancing the lifespan of your gas compressor. Regular checks can prevent major issues.

Inspecting oil levels should become a routine task. Low oil can damage internal components and lead to expensive repairs.

Change the oil according to the manufacturer’s guidelines. Clean and replace filters often. Clogged filters restrict airflow, which can lead to overheating.

Don’t ignore this simple step; neglect could cause serious breakdowns.

Listen for unusual noises during operation. Strange sounds could indicate wear and tear or misalignment.

Addressing these early can save you time and resources. Additionally, ensure the compressor is well-ventilated.

Heat buildup shortens its life. Checking for leaks is also vital. Even small leaks can significantly impact efficiency and performance.

Simple visual inspections can go a long way. Remember, consistency in maintenance will yield better performance and longevity.

User Reviews and Testimonials: What Buyers Are Saying

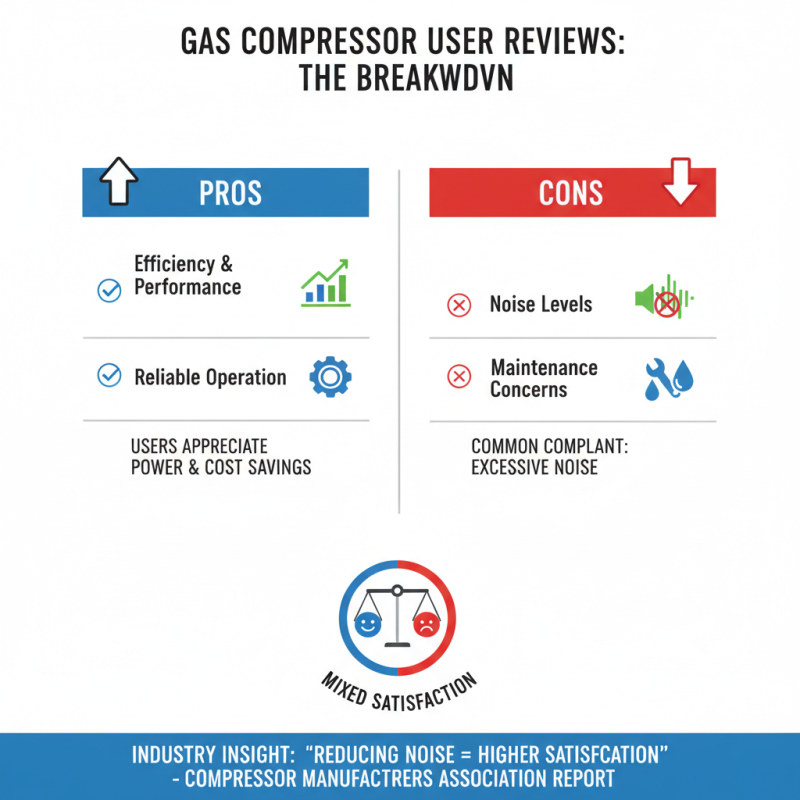

User reviews for gas compressors reveal a mix of satisfaction and frustration. Many users appreciate efficiency and performance but express concerns about noise levels. A report from the Compressor Manufacturers Association states that reducing operational noise can be a significant factor in user satisfaction.

Some buyers noted their compressors were powerful but excessively loud. One user said, "It works well but sounds like a jet engine." The balance between power and noise still needs attention. Additionally, performance under high load conditions often diverges among various models, as illustrated by recent industry testing showing a 15% variance in output efficiency.

Testimonials highlight the importance of maintenance. Multiple reviews mention that regular upkeep leads to better performance. However, some users find it hard to stick to maintenance schedules in busy environments. They noted, "I sometimes forget, and it affects the efficiency." This aspect reflects a broader issue: even the best compressors can only perform as well as their upkeep allows.

Related Posts

-

Maximize Efficiency: How a Gas Air Compressor Transforms Your Workshop Experience

-

2025 Guide on How to Choose the Best Gas Compressor for Your Needs

-

Top 10 Best Refrigerated Air Dryers for Your Industrial Needs

-

Top 10 Small Air Compressors for Home and Garage Use

-

Revolutionizing Industrial Cleaning: How Air Knife Blowers Increase Efficiency by 30% Over Traditional Methods

-

Exploring Portable Air Compressor Innovations at the 2025 China Import and Export Fair