24 Hour Service

24 Hour Service- 800.825.3222

- Now Hiring

- Request A Quote

Blog

2025 Guide on How to Choose the Best Gas Compressor for Your Needs

In the realm of industrial applications, choosing the right gas compressor is a critical decision that can significantly impact efficiency and operational costs. As industry expert Dr. Emily Carter, a leading engineer in gas compression technology, aptly states, “The right gas compressor is not just a machine; it’s a cornerstone of productivity in any gas-handling operation.” With the rapid advancements in compressor technology and the diverse needs of different sectors, understanding the unique requirements of your operations is essential for making an informed choice.

This guide aims to equip you with the knowledge needed to select the best gas compressor for your needs in 2025. From evaluating performance metrics to considering budget constraints and maintenance requirements, several factors come into play when making this important decision. By delving into the features and capabilities of various gas compressors, we can navigate the complexities of the market and choose a solution that maximizes productivity while minimizing costs. Whether you’re in oil and gas, manufacturing, or any other sector relying on compressed gas, this guide will provide you with the expertise necessary to ensure your investment is sound and efficient.

Understanding Different Types of Gas Compressors Available in the Market

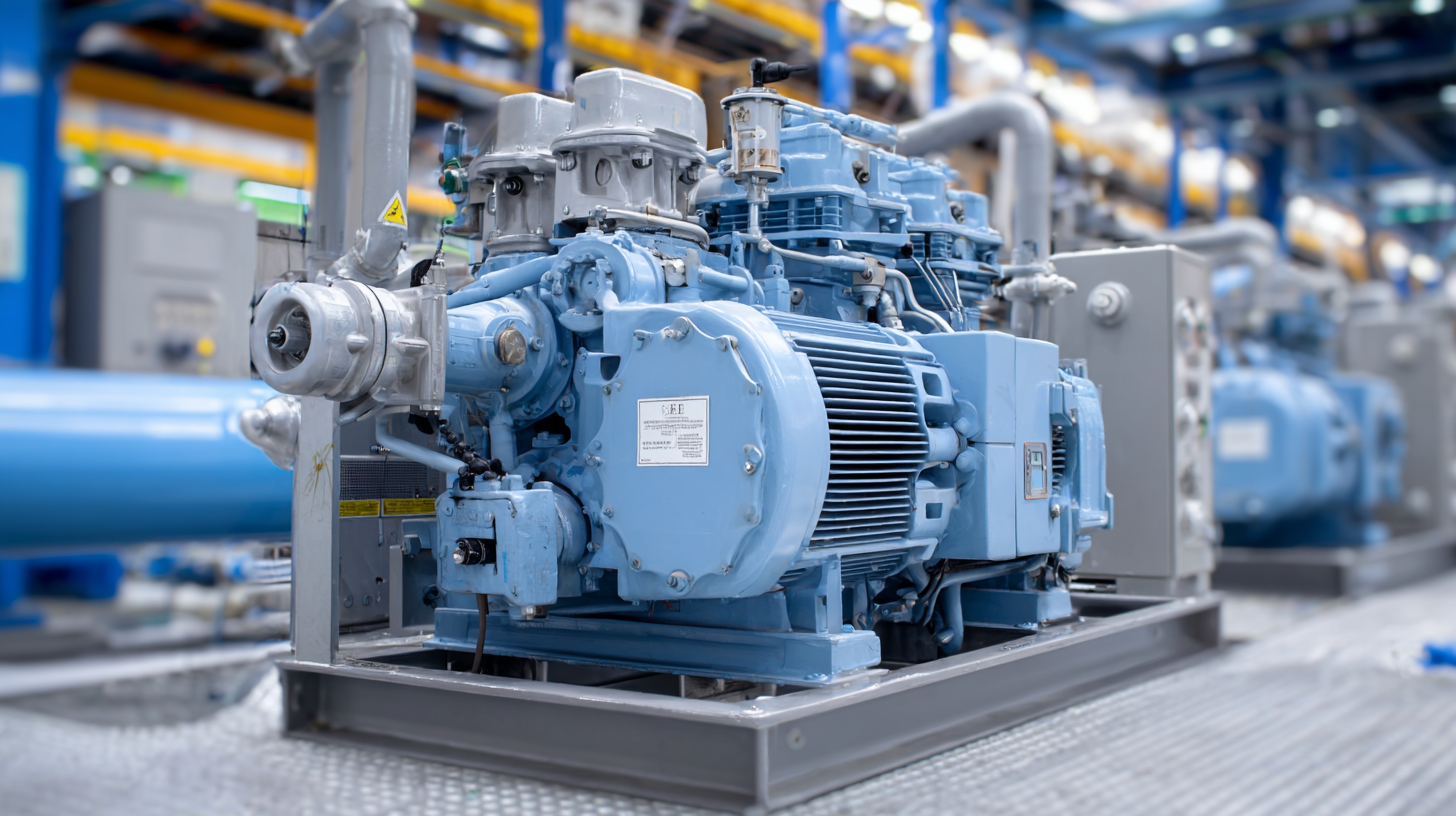

When selecting the best gas compressor for your needs, it's crucial to understand the various types available in the market. There are two primary categories: positive displacement and dynamic displacement compressors. Positive displacement compressors, such as reciprocating models, are preferred for applications requiring high pressure and low flow rates. In contrast, dynamic compressors, including centrifugal and axial types, excel in high flow rate scenarios with relatively low pressure increases.

Recent market insights highlight significant growth in the gas compressor sector. The global natural gas compressor market is projected to reach USD 7.8 billion by 2034, with a compound annual growth rate (CAGR) of 4.1% from 2025 to 2034. Similarly, the reciprocating hydrogen compressor market is set to expand from approximately $1.43 billion in 2025 to an estimated $2.12 billion by 2032, demonstrating a robust demand for this technology due to the increasing focus on hydrogen as a clean energy source. Understanding these market dynamics not only aids in selecting the right compressor type but also ensures alignment with future industry trends.

2025 Guide on How to Choose the Best Gas Compressor for Your Needs

| Type of Gas Compressor | Ideal Applications | Advantages | Disadvantages | Cost Range |

|---|---|---|---|---|

| Reciprocating Compressor | Industrial applications, gas transportation | High efficiency, suitable for high pressure | Loud operation, requires regular maintenance | $5,000 - $30,000 |

| Rotary Screw Compressor | Manufacturing, HVAC systems | Continuous operation, low noise | Higher initial cost, less efficient at low loads | $10,000 - $50,000 |

| Centrifugal Compressor | Large-scale industrial processes | High flow rates, efficient at constant speed | Not suitable for low flow applications, complex system | $20,000 - $200,000 |

| Scroll Compressor | Refrigeration, air conditioning | Compact size, quiet operation | Limited pressure capability, generally lower efficiency | $2,000 - $15,000 |

Key Factors to Consider When Selecting a Gas Compressor for Your Application

When selecting the best gas compressor for your application, several key factors must be considered to ensure optimal performance and efficiency. First, understanding the type of gas to be compressed is essential, as different gases require specific compressor designs.

Reciprocating compressors, for instance, are ideal for high pressure and low flow applications, particularly in the hydrogen compression market, which is projected to see significant growth in the coming years. Additionally, the compressor's efficiency rating can greatly impact operational costs; thus, investing in a model with a high efficiency can lead to substantial savings over time.

Another important consideration is the compressor's capacity and flow rate, which should align with your operational requirements. It's vital to evaluate both the peak demand and the average use to select a unit that can handle your specific needs without causing undue strain. Moreover, consider the reliability and maintenance needs of a compressor, as these factors contribute to overall uptime and productivity.

Choosing a model that balances capacity, efficiency, and ease of maintenance will ultimately support the long-term success of your operations in the evolving gas compressor market.

Comparing Reciprocating and Rotary Gas Compressors: Pros and Cons

When considering the best gas compressor for your needs, it's essential to weigh the pros and cons of

reciprocating and

rotary gas compressors.

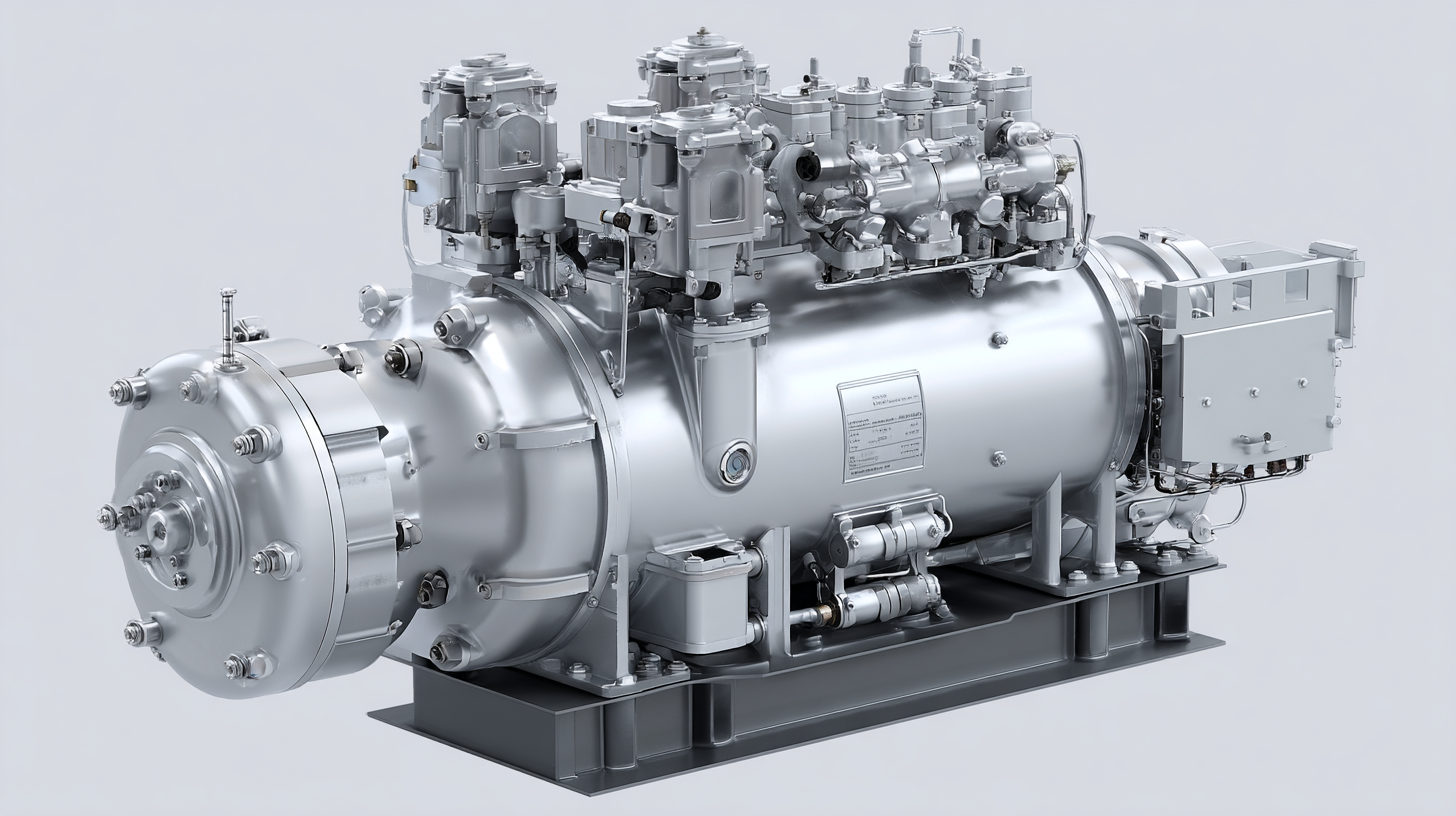

Reciprocating compressors use pistons to compress gas, making them suitable for high-pressure applications.

They are often more compact and less expensive upfront, which can be advantageous for individuals or businesses on a tight budget.

However, they can be noisier and require more maintenance over time.

On the other hand, rotary gas compressors, particularly rotary screw models, are gaining popularity due to their

efficiency and

reliability. A recent survey found that a significant majority of service truck operators prefer rotary screw compressors for their ability to provide continuous airflow and operate with less noise.

These compressors typically offer lower operational costs and longer lifespans, although their initial investment can be higher.

Tips:

When choosing between the two types, assess your specific application needs such as pressure requirements and space constraints.

Consider future maintenance costs and potential noise levels, especially if the compressor will be used in a sensitive environment.

Additionally, evaluate your long-term operational costs to make the most cost-effective choice.

Analyzing the Efficiency and Output of Various Gas Compressor Types

When selecting a gas compressor, understanding the efficiency and output of various types is crucial. The main categories of gas compressors include rotary, centrifugal, and reciprocating models, each with distinct operational characteristics and applications.

When selecting a gas compressor, understanding the efficiency and output of various types is crucial. The main categories of gas compressors include rotary, centrifugal, and reciprocating models, each with distinct operational characteristics and applications.

Rotary compressors, known for their continuous and smooth operation, are often preferred for large-scale applications requiring consistent airflow. On the other hand, centrifugal compressors excel in handling high volumes of gas at lower pressures, making them ideal for oil and gas applications.

Reciprocating compressors, meanwhile, offer higher pressure capabilities and are well-suited for applications requiring precise gas flow rates. Analyzing the specific efficiency ratings and output capacities of these compressors will guide users in making informed decisions tailored to their operational needs.

As the gas compression market continues to evolve, advancements in technology will likely lead to improved performance and energy efficiency across all compressor types, emphasizing the importance of staying updated with the latest industry trends and innovations.

Maintenance and Longevity: Choosing a Durable Gas Compressor for Your Needs

When selecting a gas compressor, durability and maintenance should be at the forefront of your decision-making process. A reliable compressor not only minimizes downtime but also ensures longevity, ultimately saving you time and money. Look for models constructed from high-quality materials that can withstand operational stresses and environmental factors. Components such as casings, pistons, and valves should be made from robust alloys designed to endure corrosive gases and high temperatures.

Additionally, consider the maintenance requirements of the gas compressor. A model that offers easy access to key parts for routine checks and servicing can significantly enhance its lifespan. Regular maintenance, including checking lubricants and seals, can prevent costly repairs and extend the life of the unit. Furthermore, brands that provide thorough manuals and customer support can be invaluable in maintaining your compressor’s performance over the years. By focusing on durability and ease of maintenance, you can select a gas compressor that meets your needs effectively without unnecessary complications.

Related Posts

-

What is a Small Air Compressor and How Can It Benefit Your Business

-

How to Choose the Right Air Compressor Pump for Your Specific Needs

-

Expert Guide to Affordable Air Compressor Repair Techniques for Homeowners

-

How to Select the Right Air Dryer for Your Compressor Needs

-

7 Essential Tips for Choosing the Best Oil Free Air Compressor

-

Maximize Efficiency: How a Gas Air Compressor Transforms Your Workshop Experience